Well-designed Hdpe Bottle Washing Line - Continous None-stop Hydraulic Screen Changer for Extruder – Polestar

Well-designed Hdpe Bottle Washing Line - Continous None-stop Hydraulic Screen Changer for Extruder – Polestar Detail:

Description

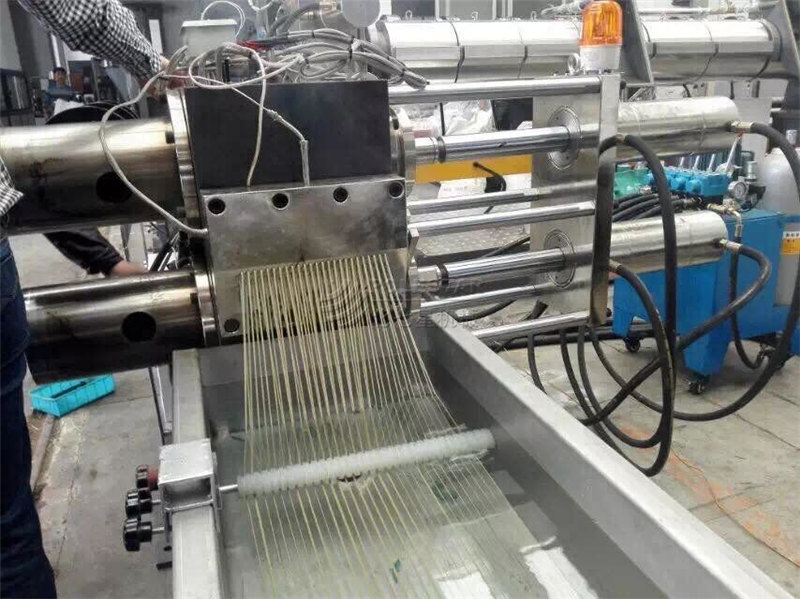

The New fast changing or as is called, the plate screen changer is widely used for the production of various plastics and chemical fibers. It is of high performance/price ratio, and ensures the screen changing without machine halt, or any material leakage under high pressure. Therefore, it is especially applicable to large scale machines of film blowing, pipe making, plate making and granulating, etc.

Our Screen Changer Advantages

1. Large capacity, large filtering area: Capacity can be reached 20-11300 kg/h, Filtering area: 30-10000 cm2.

2. Continuous process: no material leakage, no need to stop the machine when changing the screen, no production disruption or interference

3. High pressure and temperature resistant: max operation pressure can be 600 bar, temperature : 330°C.

4. Automatic without manual work: fully automatic belt filter without manual work; back flush function: screen washing online to replace manual work.

5. Good wear-resistance: high-quality, high-performance alloy material after precise finishing and particular hardening.

6. Easy maintenance: easy to install and maintain, reliable and economical.

7. Wide range of choices: we provide different dimensions of product which can meet various needs.

Technical Data

| Type | Screen—Dm(mm) | Heating Power(kw) | Pressure(Mpa) | Output(Kg/h) |

| DHB-70 | Φ70 | 4.4 | ≤50 | 60-250 |

| DHB-100 | Φ100 | 6.8 | ≤50 | 110-400 |

| DHB-120 | Φ120 | 8.6 | ≤50 | 140-550 |

| DHB-150 | Φ150 | 9.8 | ≤50 | 200-800 |

| DHB-170 | Φ165 | 10.6 | ≤50 | 300-1000 |

| DHB-200 | Φ200 | 12 | ≤50 | 400-1200 |

| DHB-250 | Φ250 | 16.4 | ≤50 | 600-1800 |

| DHB-300 | Φ300 | 16.4 | ≤50 | 800-2500 |

Product detail pictures:

Related Product Guide:

Our commission should be to provide our end users and clients with very best excellent and aggressive portable digital products and solutions for Well-designed Hdpe Bottle Washing Line - Continous None-stop Hydraulic Screen Changer for Extruder – Polestar , The product will supply to all over the world, such as: Swedish, Wellington, Czech republic, To have much more enterprise. ompanions, we've got updated the item list and seek for optimistic co-operation. Our web-site shows the latest and complete information and facts about our goods list and company. For further acknowledge, our consultant service group in Bulgaria will reply to all of the inquiries and complications immediately. They're going to make their finest effort to meet buyers need. Also we support the delivery of absolutely free samples. Business visits to our business in Bulgaria and factory are generally welcome for a win-win negotiation. Hope to expertise a happy company co-operation perform with you.

Adhering to the business principle of mutual benefits, we have a happy and successful transaction, we think we will be the best business partner.

Products categories

Want To Add Sky To Your Design?

Contact us today for a design consultation.