Renewable Design for Plastic Extrusion Machine Extruder - Stainless Steel Vertical Plastic Granules Mixer – Polestar

Renewable Design for Plastic Extrusion Machine Extruder - Stainless Steel Vertical Plastic Granules Mixer – Polestar Detail:

Description

Vertical plastic mixer is an ideal plastic mixer machine for mixing plastics, with the rapid rotation of the screw, the raw materials are lifted from the bottom of the barrel from the center to the top, and then scattered to the bottom by umbrella flying, so that the raw materials can be stirred up and down in the barrel, and a large number of raw materials can be evenly mixed in a short time.

Advantages

1.The plastic mixer machine is composed of mixing tank body, mixing tank cover, mixer, support, transmission device, shaft seal device, etc., and can be equipped with heating device or cooling device according to the process requirements; in the mixing process, the feeding control, discharge control, mixing control and other manual automatic control are available, which fully embodies the standardized and humanized design.

2.Mixing tank body, mixing tank cover, mixer, shaft seal, etc., can be made of carbon steel or stainless steel according to different process requirements. .

3.The mixing tank body and the mixing tank cover can be sealed with flanges or welded. The process pipe holes such as feeding, discharging, observation, temperature measurement, pressure measurement, steam fraction and safe emptying can be carried out according to the process requirements.

4.The upper part of the mixing tank cover is equipped with a transmission device (motor or reducer), and the agitator in the mixing tank is driven by the drive shaft. .

5.The shaft seal device can be in many forms, such as machine seal or packing, labyrinth seal and so on (determined according to the needs of users).

Technical Data

|

Model |

Power(kw) |

Capacity(KG) |

Dimension(mm) |

Rotating Speed |

Heating Power |

Blower |

|

BQX-500L |

2.2 |

500 |

1170*1480*2425 |

300 |

12 |

0.34 |

|

BQX-1000L |

3 |

1000 |

1385*1800*3026 |

300 |

18 |

1 |

|

BQX-2000L |

4 |

2000 |

1680*2030*3650 |

300 |

30 |

1.5 |

|

BQX-3000L |

5.5 |

3000 |

2130*2130*3675 |

300 |

38 |

2.2 |

|

BQX-5000L |

7.5 |

5000 |

3500*3500*3675 |

300 |

38 |

2.2 |

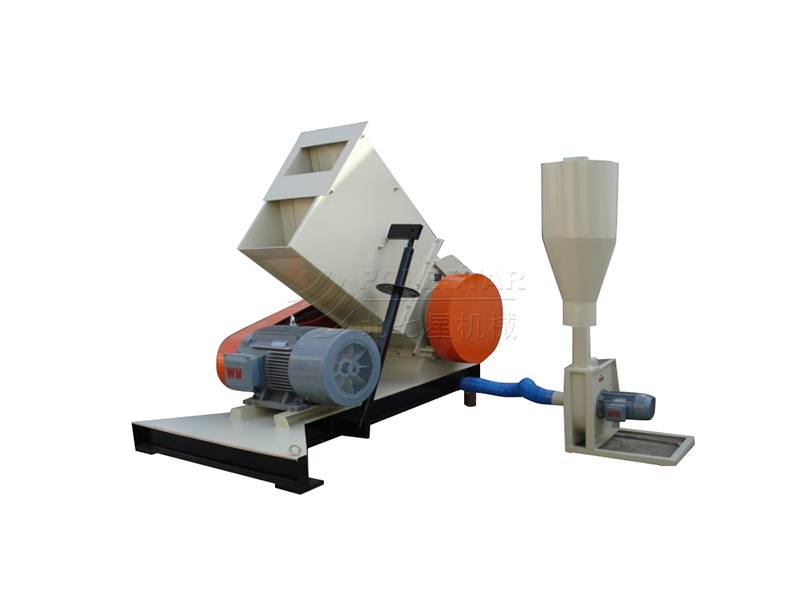

Product detail pictures:

Related Product Guide:

Our purpose is to fulfill our clients by offering golden company, great price and premium quality for Renewable Design for Plastic Extrusion Machine Extruder - Stainless Steel Vertical Plastic Granules Mixer – Polestar , The product will supply to all over the world, such as: Armenia, UK, Swedish, As a well educated, innovative and energetic staff,we are responsible for all elements of the research, design, manufacturing, sales and distribution. With studying and developing new techniques,we are not only following but also leading the fashion industry. We listen attentively to the feedback from our customers and provide instant communication. You will instantly feel our expertise and attentive service.

Reasonable price, good attitude of consultation, finally we achieve a win-win situation,a happy cooperation!

Products categories

Want To Add Sky To Your Design?

Contact us today for a design consultation.