Quality Inspection for Pipe Shredder - Continous None-stop Hydraulic Screen Changer for Extruder – Polestar

Quality Inspection for Pipe Shredder - Continous None-stop Hydraulic Screen Changer for Extruder – Polestar Detail:

Description

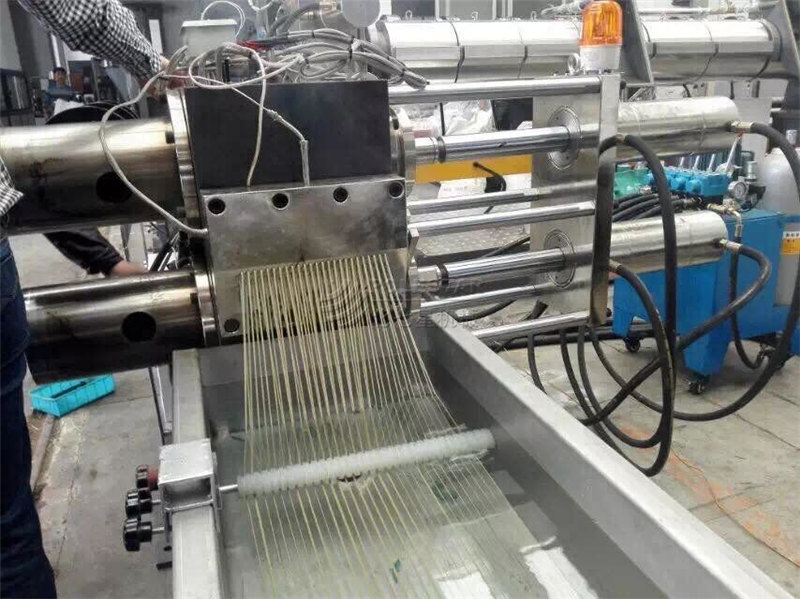

The New fast changing or as is called, the plate screen changer is widely used for the production of various plastics and chemical fibers. It is of high performance/price ratio, and ensures the screen changing without machine halt, or any material leakage under high pressure. Therefore, it is especially applicable to large scale machines of film blowing, pipe making, plate making and granulating, etc.

Our Screen Changer Advantages

1. Large capacity, large filtering area: Capacity can be reached 20-11300 kg/h, Filtering area: 30-10000 cm2.

2. Continuous process: no material leakage, no need to stop the machine when changing the screen, no production disruption or interference

3. High pressure and temperature resistant: max operation pressure can be 600 bar, temperature : 330°C.

4. Automatic without manual work: fully automatic belt filter without manual work; back flush function: screen washing online to replace manual work.

5. Good wear-resistance: high-quality, high-performance alloy material after precise finishing and particular hardening.

6. Easy maintenance: easy to install and maintain, reliable and economical.

7. Wide range of choices: we provide different dimensions of product which can meet various needs.

Technical Data

| Type | Screen—Dm(mm) | Heating Power(kw) | Pressure(Mpa) | Output(Kg/h) |

| DHB-70 | Φ70 | 4.4 | ≤50 | 60-250 |

| DHB-100 | Φ100 | 6.8 | ≤50 | 110-400 |

| DHB-120 | Φ120 | 8.6 | ≤50 | 140-550 |

| DHB-150 | Φ150 | 9.8 | ≤50 | 200-800 |

| DHB-170 | Φ165 | 10.6 | ≤50 | 300-1000 |

| DHB-200 | Φ200 | 12 | ≤50 | 400-1200 |

| DHB-250 | Φ250 | 16.4 | ≤50 | 600-1800 |

| DHB-300 | Φ300 | 16.4 | ≤50 | 800-2500 |

Product detail pictures:

Related Product Guide:

That has a sound small business credit, great after-sales service and modern production facilities, we've earned an outstanding standing amid our buyers across the earth for Quality Inspection for Pipe Shredder - Continous None-stop Hydraulic Screen Changer for Extruder – Polestar , The product will supply to all over the world, such as: Porto, Milan, Denmark, You can always find the solutions you have to have in our company! Welcome to inquire us about our product and anything we know and we can help in auto spare parts. We have been looking forward to work with you for a win-win situation.

This company conforms to the market requirement and joins in the market competition by its high quality product, this is an enterprise that have Chinese spirit.

Products categories

Want To Add Sky To Your Design?

Contact us today for a design consultation.