Professional Design Cardboard Shredder Machine - Waste Plastic Bottle Label Remover Machine – Polestar

Professional Design Cardboard Shredder Machine - Waste Plastic Bottle Label Remover Machine – Polestar Detail:

Description

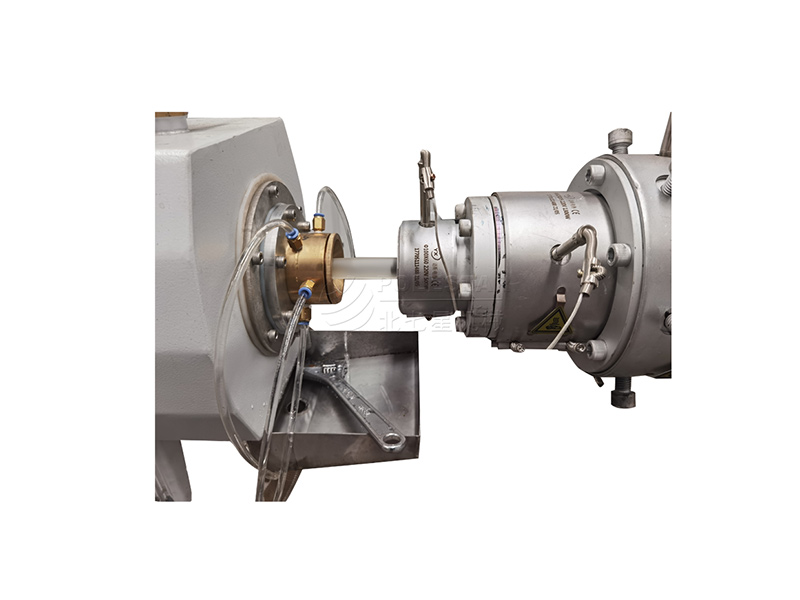

Bottle label remover design is stable speed, don’t need to convert speed, easily operating, you just feed material into material. There are leaves on the axle, leaves has lots of functional screw for removing label, while running of screw, the label from bottle will be scratched down, and rinsing out of net by water, and washing the bottles. The removing rate is decided by the original status of bottles, compressed bottle is about 60-80%, for uncompressed bottle is about 80-90%, the wasting rate is about 5%.

1) This bottle label remover is used to pre-treatment of the bottle (include pet bottle, pe bottle )before washing or crushing. The label on the bottle can be removed up to 95% (include paper label), and the cover of the bottle will be removed up to 70%.

2) The label will be peel off by self-friction.

3) The bottles are feed from the top of the machine, and discharge from the bottom.

4) This bottle label remover machine is used for new way of washing line. Use this machine can have high purity PET/PP flakes.

5) The capacity for this machine is from 500-2000kg/h.

Competitive Advantage

Polestar company is professional in plastic recycling, which manufacture series recycling plastic machines, plastic recycling machine(PET bottle recycling machine; PE/PP film bags recycling machine, HDPE bottle /PP barrel recycling machine, and PET EPS ABS recycling machine etc). If you want more details about plastic recycling machine, please do not hesitate to let me know! Welcome to our factory!

Technical Data

| Model | TPJ-Ⅰ | TPJ-Ⅱ | TBJ-Ⅲ | TBJ-Ⅳ |

| Power(kw) | 7.5 | 11 | 22 | 22 |

| Fan power(kw) | 3 | 5.5 | 7.5 | —- |

| Width(mm) | 2500 | 3000 | 3250 | 1100 |

| Length(mm) | 4500 | 5500 | 6500 | 3480 |

| Height(mm) | 3500 | 3950 | 3950 | 3180 |

| Max. Capacity(kg/h) | 500 | 1000 | 1500 | 2000 |

| Type | Without water | Without water | Without water | With water |

Product detail pictures:

Related Product Guide:

To meet the customers' over-expected pleasure , we have now our solid crew to supply our greatest all round assistance which includes marketing, sales, planning, production, top quality controlling, packing, warehousing and logistics for Professional Design Cardboard Shredder Machine - Waste Plastic Bottle Label Remover Machine – Polestar , The product will supply to all over the world, such as: British, Amsterdam, Cancun, Providing Quality Items, Excellent Service, Competitive Prices and Prompt Delivery. Our products and solutions are selling well both in domestic and foreign markets. Our company is trying to be one important suppliers in China.

We have been cooperated with this company for many years, the company always ensure timely delivery ,good quality and correct number, we are good partners.

Products categories

Want To Add Sky To Your Design?

Contact us today for a design consultation.