High Precision PPR Pipe Mould

Description

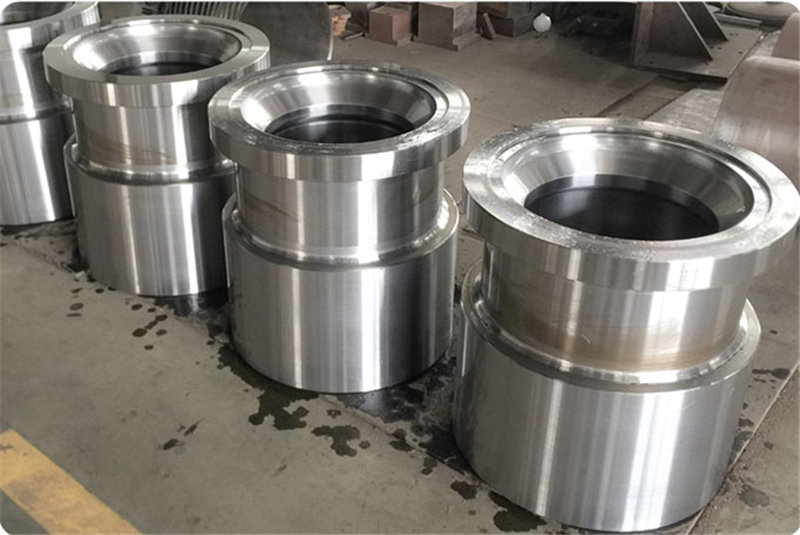

Extrusion die head apply spiral structure, each material flow channel is placed evenly. Each channel is after heat treatment and mirror polishing to ensure material flow smoothly. Die head structure is compact and also provide stable pressure, always from 19 to 20Mpa. Under this pressure, pipe quality is good and very little effect on the output capacity. Can produce single layer or multi-layer pipe.

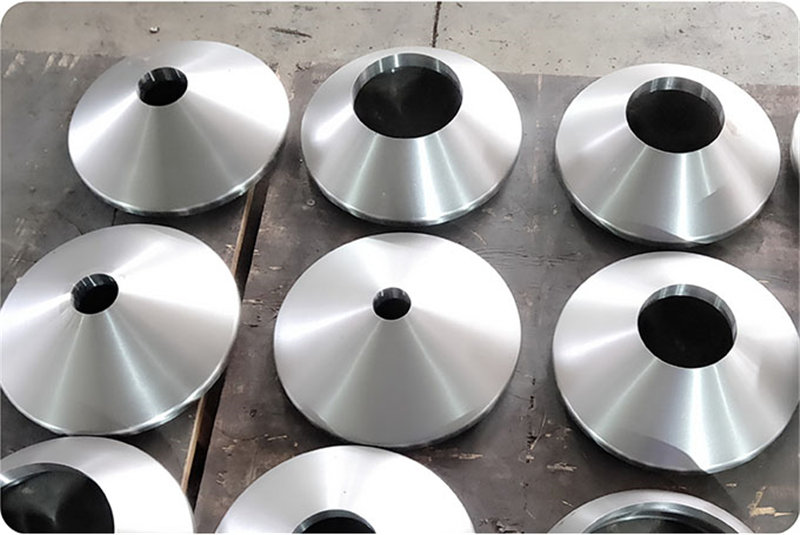

CNC Processing

Every part of extrusion die head is processed by CNC to ensure precision.

High Quality Material

Apply high quality material for extrusion die head. Die head has high strength and will not deform during long time use under high temperature condition.

Smooth Flow Channel

Have mirror polishing on flow channel and every part which contacts with melt. To make material flow smoothly.

Characteristics

| Name | ppr pipe mould |

| Mould material | 3Cr17, 3Cr17MoNiV, DIN1.2316 or as per your request |

| Mould cavity | 1 or multi-cavity |

| Mould composition | Die head, aluminum heating band, calibrators & water tank |

| Moulds scope | Moulds for seals, pinch strips, pushing rails, etc in household appliance industry; Moulds for films, grinding pieces and weather strips in automobile industrial; Moulds for drawer plates, drawer covers, baffle plates in furniture industry; Moulds for step strips, trim strips, newspaper binder strips, etc in film industry; |

| Feature | Technology of multi-color co-extrusion, soft-hard co-extrusion steel-plastic co-extrusion and different material co-extrusion |

| Test | Mould will be tested to get the satisfy sample before deliver |

| Sample | Sample will be arranged by express courier for customer approval |

| Lead time | 20 days |

| Package | Poly wood case for exporting, each mould will be cleaned before packing. |

| Quality assurance | CE ,ISO9001 |

Products categories

Want To Add Sky To Your Design?

Contact us today for a design consultation.