PLC Famous Brand Plastic Pipe Haul off Machine

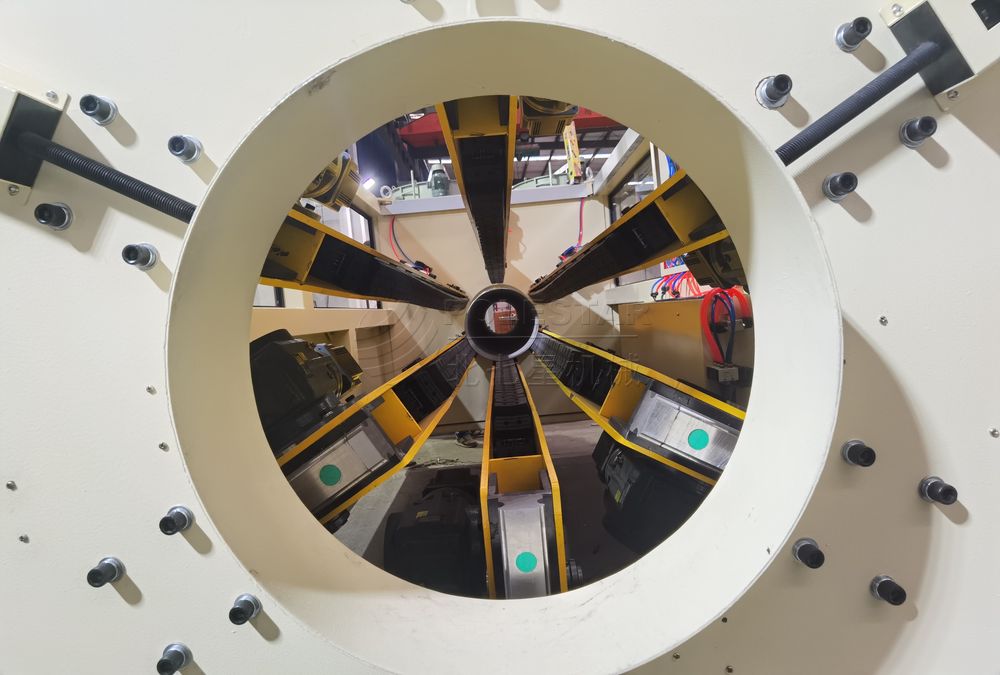

Haul Off Unit

Plastic pipe haul off machine provides sufficient traction force to pull pipe stably. According to different pipe sizes and thickness, our company will customize traction speed, number of claws, effective traction length. To ensure match pipe extrusion speed and forming speed, also avoid deformation of pipe during traction.

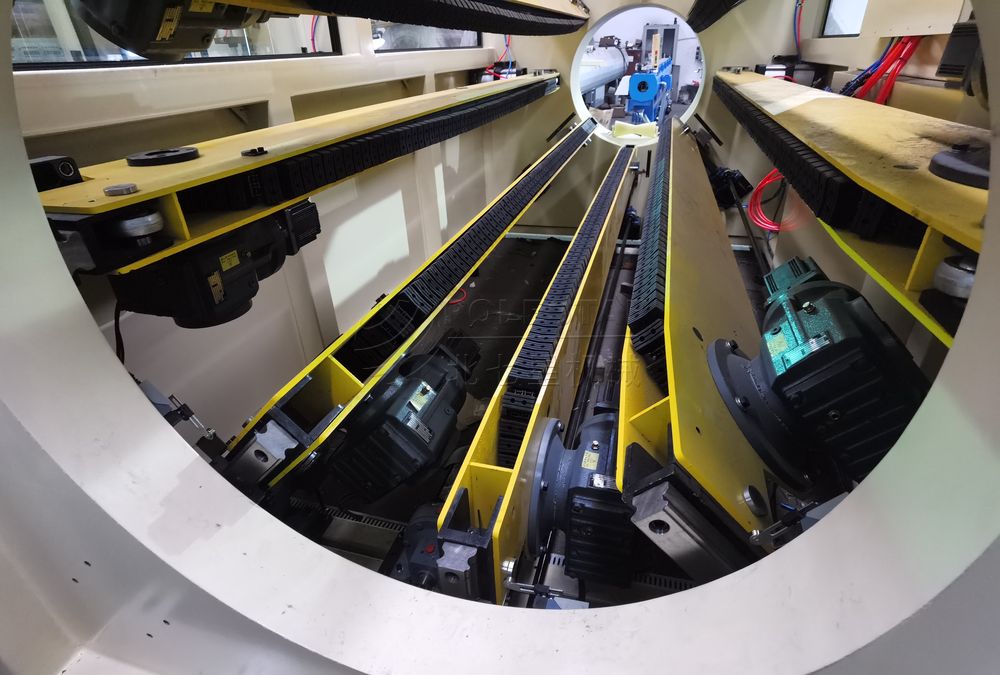

Separate Traction Motor

Each claw has its own traction motor, in case when one traction motor stop working, other motors can still working, choose servo motor to have bigger traction force, more stable traction speed and wider range of traction speed.

Claw Adjustment Device

All claws are connected to each other, when adjusting position of claws to pull pipe in different sizes, all claws will move together. This will make operation faster and easier.

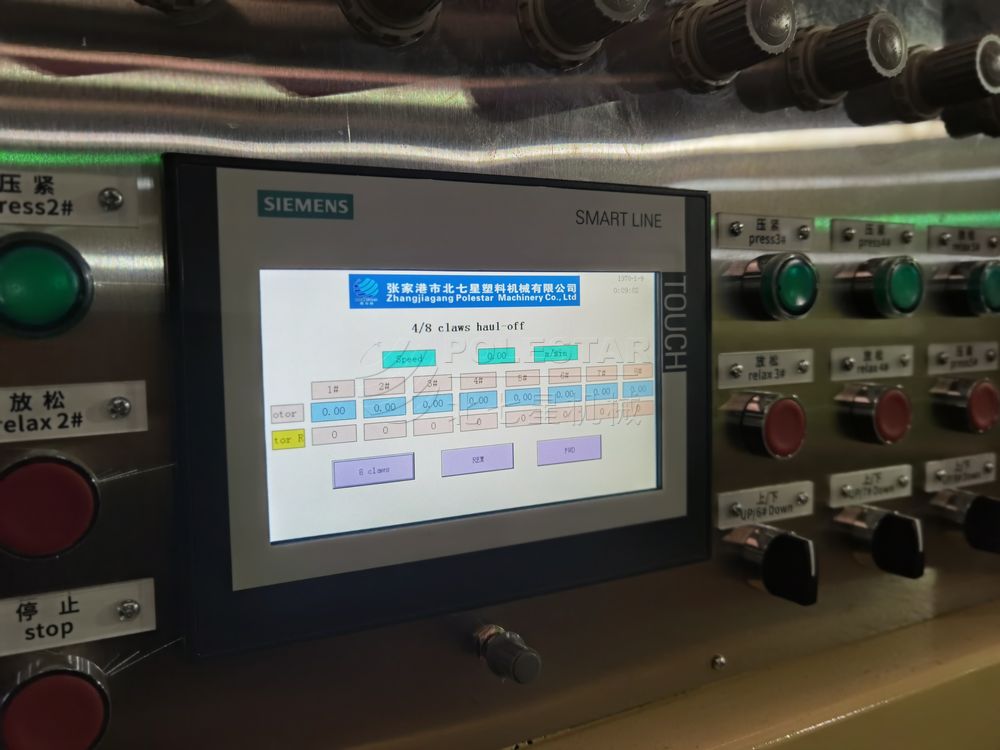

User Friendly Design

With Siemens hard ware and user friendly software designed by our company. Have synchronized function with extruder, make operation easier and faster. Also customer can choose only some of claws to work to pull much smaller pipes.

Separate Air Pressure Control

Each claw with it own air pressure control, more accurate, operation is easier.

Characteristics

|

Model |

Pipe Range |

NO of Raction belts

|

Drive Motor Power |

Peak Traction |

Max. Speed |

|

(mm) |

(kw) |

(N) |

(m/min) |

||

|

QY-32 |

φ6-32 |

2 |

2x0.75 |

3000 |

30 |

|

QY-75 |

φ16-75 |

2 |

2x1.1 |

10000 |

15 |

|

QY-160 |

φ20-160 |

2 |

2x1.5 |

15000 |

10 |

|

QY-250 |

φ50-250 |

3 |

4.5 |

20000 |

8 |

|

QY-315 |

φ75-315 |

4 |

6 |

25000 |

8 |

|

QY-450A |

φ110-450 |

4 |

4.4 |

25000 |

6 |

|

QY-450B |

φ110-450 |

4 |

4.4 |

30000 |

6 |

|

QY630A |

φ200-630 |

6 |

6x1 |

35000 |

4 |

|

QY-800 |

φ315-800 |

8 |

8x1 |

38000 |

2.75 |

Products categories

Want To Add Sky To Your Design?

Contact us today for a design consultation.