Waste PET Bottles Washing Machine

Description

PoleStar plastic reycling machine is designed for recycling daily-use plastic products. Plastic recycing is important for enviroment. We are professional in manufacturing plastic recycling machine. Plastic recycling plant includes grading, crushing, washing, drying and so on.

Plastic recycling machine is researched, design and manufactured by our company, integration of Europe technology, plastic recycling machine has features as high efficiency, working stable, low humidity content(less than 1%). We use good quality on our washing recycling machine(SUS-304,more than 3mm thickness) ensures whole recycling equipment long service life time.

PET bottle recycling machine is machine to recycle plastic pet bottles, which get rid of PE/ PP label, cap, oil, garbage, protect the environment, avoid white pollution.

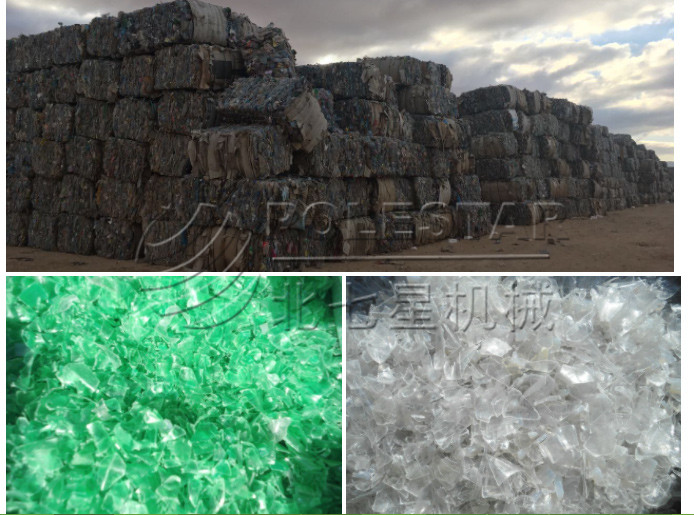

PET bottle recycling plant is composed of separator, crusher, cold & hot washing system, dewatering, drying, packing system, etc. This pet bottle flakes recycling machine line takes compacted bales of PET bottles and turns them into clean, contaminant-free PET flakes that can be used in producing polyester staple fiber or pelletized into granules for use in manufacturing other PET products. Our pet bottle washing machine is high automatic and efficient. Our pet bottle washing machine is welcomed by customers also pet bottle recycling machine price is good competitive.

Final Product

Surface moisture: 1%

PVC content: max. 500 ppm(According to your worker sorting)

Glue content: max. 4.000 ppm (Flakes included)

Label content: max. 500 ppm(According to your worker sorting)

HDPE / PP content: max. 500 ppm

PET dust: max. 0.1 %

Metal content: max. 50 ppm

Competitive Advantage

1. High automation level, try best to reduce your cost on labor and ensure high processing capacity

2. Friendly control system (PLC integrated & separated control on each machine) and Touch screen panel, easy for operation, monitor and emergency stop.

3. All parts contacting with plastic material and water are made of high-quality 304 or 316 stainless steel; Ensure no second pollution to flakes.

4. Ideal impurity removal effect.

5. Siemens contactor, RKC temperature controller.

Main Features

1. High automation,less man power, low energy consumption, high output;

2. Provide whole solution for by-products during production, for example: variegated bottles, non-PET material, sewage water, labels, caps, metal and etc.

3. With a materials pre-treatment system such as pre-washer, label processing module, highly improve quality of end products;

4. Through multiple cold flotation, hot washing and friction washing, fully remove the impurities, such as glue, organic and inorganic residue;

5. The reasonable process design, reduce maintenance cost and bring convenient operation.

Technical Data

|

Model |

Output (kg/h) |

Power Consumption (kW/h) |

Steam (kg/h) |

Detergent (kg/h) |

Water (t/h) |

Installed Power (kW/h) |

Space (m2) |

| PET-500 |

500 |

180 |

500 |

10 |

0.7 |

200 |

700 |

|

PET-1000 |

1000 |

170 |

600 |

14 |

1.5 |

395 |

800 |

|

PET-2000 |

2000 |

340 |

1000 |

18 |

3 |

430 |

1200 |

|

PET-3000 |

3000 |

460 |

2000 |

28 |

4.5 |

590 |

1500 |

Products categories

Want To Add Sky To Your Design?

Contact us today for a design consultation.