Plastic PE Pipe Extruder Machine

Description

PE extruder is used in Polyethylene extrusion to extrude PE,polyolefin and other thermoplastics.

Polyethylene extrusion machine can processes all kinds of plastic products with auxiliary machine concerned, such as film,pipe,bar,plate,thread,ribbon,insulating layer of cable,hollow products and so on.

Polythene extruder machine is advanced and production capacity is high. Hdpe ldpe extruder machine plasticization is good ,and ldpe extruder machine energy consumption is low. It adopt hard tooth face of gear for transmission , it has advantage of low noise,smooth operation ,large loading,long use-life and so on.

Application

PE water & Gas PIPE EXTRUSION.

PE extruder is mainly used to Polyethylene extrusion for pipe,sheet,bar and other plastic products from the PE material equipped with different type of machine and downstream.

For SJ serial screw extruder,the screw diameter is from 20 to 200mm,and the screw L/D is 10-40. You can choose the type of the extruder according to your products,specification and capacity.

The feeding system uses YASKAWA .and main bearing adopts Japan NSK original imported parts,the extruder is good value for money.we also promise excellent after-sales service.

Competitive Advantage

Connection reliability: polyethylene pipe system connected between the use of electric hotmelt, the joint strength is higher than pipe body strength.

Good low temperature impact resistance: low temperature brittleness of polyethylene low temperature can be within a temperature range of subzero 60 to 60 degrees Celsius safe to use. Construction in winter, because of materials, impact resistance is good, tube embrittlement will not occur.

Good stress cracking resistance: HDPE has a low gap sensitivity, high shear strength and excellent anti scratch capabilities, resistance to environmental stress cracking performance is also very prominent.

Good resistance to chemical corrosion: HDPE pipe can be resistant to a variety of chemical media, corrosion, chemical substances that exist in the soil will not cause any degradation of the pipeline. Polyethylene is the Electrical insulator, it will not happen rot, rust or electrochemical corrosion phenomenon; In addition, it will not promote algae, bacteria or fungal growth.

Anti aging, long life: containing 2% to 2.5% of the uniform distribution of carbon black in polyethylene pipe can be outdoor storage or use of 50 years, will not be subjected to ultraviolet radiation damage.

Abrasion resistance: HDPE Pipe and comparison tests showed the wear resistance of steel pipe, HDPE pipe 4 times the wear resistance of steel pipe. In the mud transportation field, as compared with the steel pipe, HDPE pipe has better wear resistance, which means that HDPE pipe has a longer life and better economy.

Flexible good: HDPE pipe flexible makes it easy to bend, works by changing the pipes can be a way to bypass the obstacles towards, and in many occasions, the flexible pipe fittings to reduce consumption and lower installation costs.

Flow resistance: HDPE pipe has a smooth inner surface, the Manning coefficient of 0.009. The performance smooth and non adhesion properties ensure the HDPE pipe has a higher than traditional pipe transmission capacity, but also reduce the pipeline pressure loss and water consumption.

Technical Data

|

Model |

L/D |

Capacity(kg/h) |

Rotary speed(rpm) |

Motor power(KW) |

Central height(mm) |

|

SJ25 |

25/1 |

5 |

20-120 |

2.2 |

1000 |

|

SJ30 |

25/1 |

10 |

20-180 |

5.5 |

1000 |

|

SJ45 |

25-33/1 |

80-100 |

20-150 |

7.5-22 |

1000 |

|

SJ65 |

25-33/1 |

150-180 |

20-150 |

55 |

1000 |

|

SJ75 |

25-33/1 |

300-350 |

20-150 |

110 |

1100 |

|

SJ90 |

25-33/1 |

480-550 |

20-120 |

185 |

1000-1100 |

|

SJ120 |

25-33/1 |

700-880 |

20-90 |

280 |

1000-1250 |

|

SJ150 |

25-33/1 |

1000-1300 |

20-75 |

355 |

1000-1300 |

Single Screw Extruder

Based on 33:1 L/D ratio for screw design, we have developed 38:1 L/D ratio. Compared with 33:1 ratio, 38:1 ratio has advantage of 100% plasticization, increase output capacity by 30%, reduce power consumption up to 30% and reach almost linear extrusion performance.

Simens Touch Screen and PLC

Apply program developed by our company, have English or other languages to be input into the system.

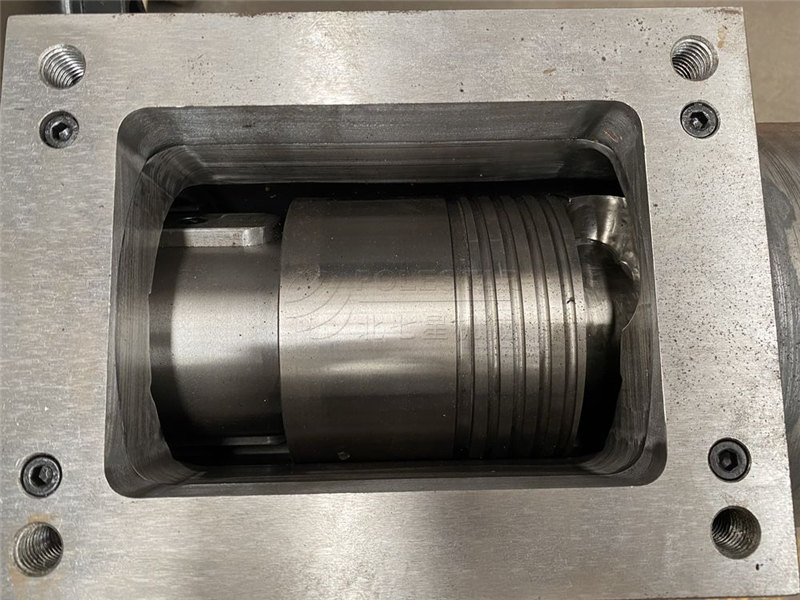

Special Design of Screw

Screw is designed with special structure, to ensure good plasticization and mixing. Unmelted material can not pass this part of screw, good plastic extrusion screw.

Spiral Structure of Barrel

Feeding part of barrel use spiral structure, to ensure material feed in stable and also increase feeding capacity.

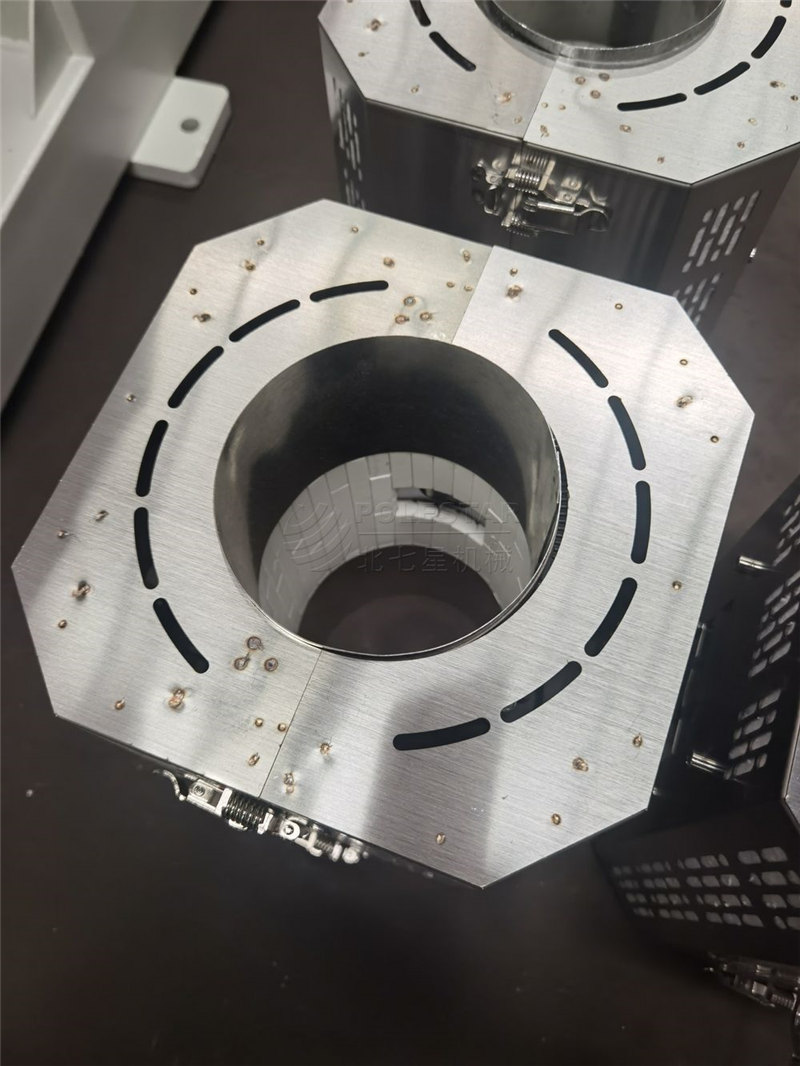

Air Cooled Ceramic Heater

Ceramic heater ensure long working life. This design is to increase the area which heater contact with air. To have better air cooling effect.

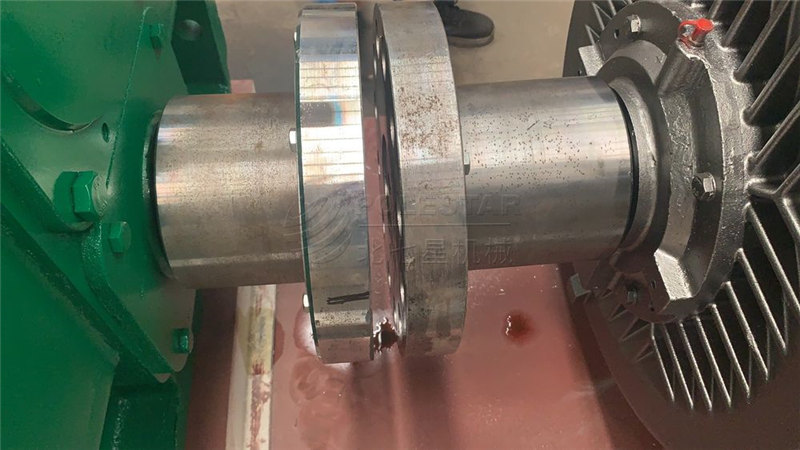

High Quality Gearbox

Gear accuracy to be ensured 5-6 grade and lower noise below 75dB. Compact structure but with high torque.

Products categories

Want To Add Sky To Your Design?

Contact us today for a design consultation.