Original Factory Plastic Granulator Machine - Central Plastic Material Feeding Conveying System – Polestar

Original Factory Plastic Granulator Machine - Central Plastic Material Feeding Conveying System – Polestar Detail:

What’s Central Conveying System

Central conveying system also called as central feeding system, is designed for the production of plastic products, realizing uninterrupted and unmanned continuous molding operations.

The variety of raw materials and the combination of multi-color materials can be changed according to needs, and the automation of the coloring process can be realized.

The system can re-use the runner in a fully automatic way, can control all feeding equipment, and prevent blockage in the storage bin, and realize full automation by setting up a central monitoring station.

The central conveying feeding system is the processing of raw material storage and via closed transportation system with a pair of multi-motor automatic controller will be a variety of different materials in accordance with the requirements to the energy savings ,as well as a way of forming machine can lower noise and pollution of the ideal automation system.For the existing raw materials preparation area of dry processing raw material, we can use a dry air to transport in order to avoid raw material again be affected with damp be affected with damp. In addition to outside the company’s unique advanced controller in the middle of the pulse dust collector.

Features

1. Safe working conditions

2. Reduce noise

3. Lower energy consumption

4. Change the using methods about the combination between mold and material of various kinds and colors according to the needs.

5. Control material convey through the central panel, realizing labor-saving.

Technical Data

|

Model |

HFV-10 |

HFV-15 |

HFV-20 |

HFV-30 |

HFV-40 |

|

Tube Diameter |

3” |

4” |

5” |

5” |

6” |

|

Motor |

10HP |

15HP |

20HP |

30HP |

40HP |

|

Wind Pressure |

-4000 |

-4000 |

-5000 |

-5000 |

-5000 |

|

Air Flow |

6 |

8 |

13 |

17 |

22 |

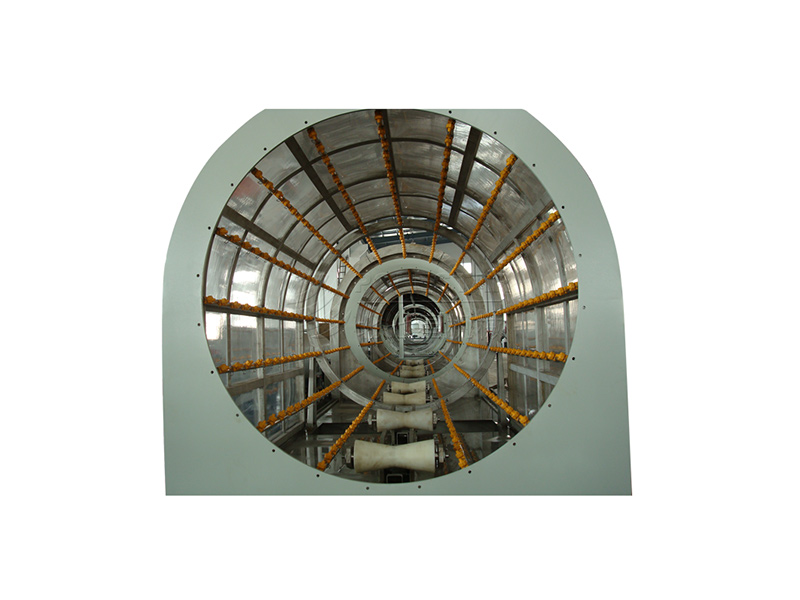

Product detail pictures:

Related Product Guide:

"Sincerity, Innovation, Rigorousness, and Efficiency" would be the persistent conception of our corporation to the long-term to establish collectively with customers for mutual reciprocity and mutual benefit for Original Factory Plastic Granulator Machine - Central Plastic Material Feeding Conveying System – Polestar , The product will supply to all over the world, such as: Bahrain, Hungary, Berlin, Each year, many of our customers would visit our company and achieve great business advancements working with us. We sincerely welcome you to visit us at any time and together we will prevail to a greater success in the hair industry.

The product manager is a very hot and professional person, we have a pleasant conversation, and finally we reached a consensus agreement.

Products categories

Want To Add Sky To Your Design?

Contact us today for a design consultation.