OEM Customized Recycling Machines Price - SRL-W Series Horizontal Mixing Unit – Polestar

OEM Customized Recycling Machines Price - SRL-W Series Horizontal Mixing Unit – Polestar Detail:

Description

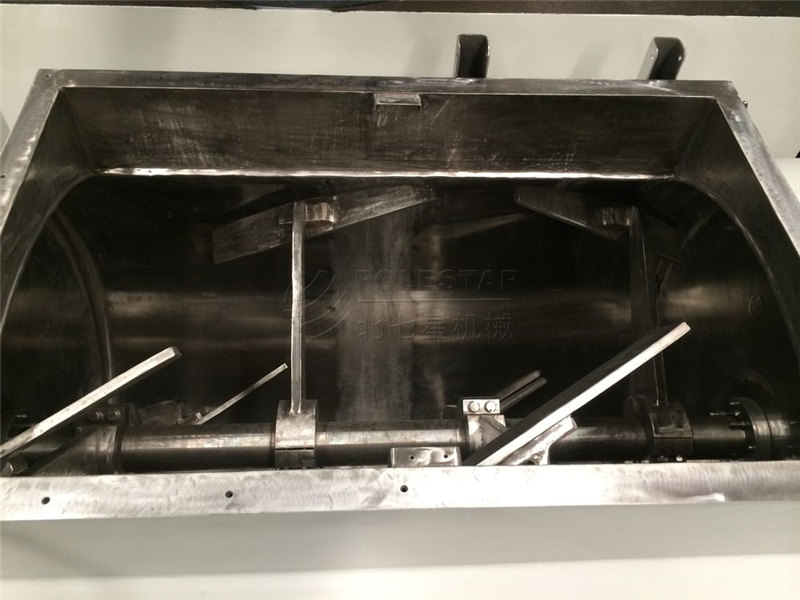

SRL-W Series horizontal hot and cold mixer are widely used for mixing, drying, and coloring for all kinds of plastic resin, especially for large production capacity. This plastic mixer machine is composed of heating and cooling mixers. Hot material from heating mixer is fed into cooling mixer for cooling to eliminate gas and avoid burning. The structure of cooling mixer is horizontal type with spiral-shape stirring blades, without dead corner and prompt discharging within short time.

Advantages

1. The seal between container and cover adopts double seal and pneumatic open for easy operation; It makes better sealing compared with traditional single seal.

2. The vane adopt big tilt angle and single layer palm, which make the material go up along the inside wall of container, and realize the aim of sufficient cooling by falling through cooling jacket

3. To ensure quality of products and improve production flexibility, safety and reliability. The temperature point inside container caused directly contact with the material which avoid material feeding running when material temperature is lower or higher than setting.

4. To avoid material leakage and improving quality of final product,discharging valve adopt plunger type gate and axial seal

The internal surface of the gate is strict with the internal wall of the container which make no dead angle.

5. Top cover has degassing device, it can get rid of water vapor in the course of hot mixing and avoid undesirable effects on the material

6. Adopting frequency conversion speed regulator, the starting and speed regulation of motor is controllable, it preventing the large current produced when starting high power motor, which produces impact on the power grid, and protect the safety of the power grid, and achieve the speed control.

Technical Data

|

SRL-W |

Heat/Cool |

Heat/Cool |

Heat/Cool |

Heat/Cool |

Heat/Cool |

|

Total volume(L) |

300/1000 |

500/1500 |

800/2000 |

1000/3000 |

800*2/4000 |

|

Effective volume(L) |

225/700 |

330/1000 |

600/1500 |

700/2100 |

1200/2700 |

|

Stirring speed(rpm) |

475/950/80 |

430/860/70 |

370/740/60 |

300/600/50 |

350/700/65 |

|

Mixing time(min) |

8-12 |

8-15 |

8-15 |

8-15 |

8-15 |

|

Power(KW) |

40/55/7.5 |

55/75/15 |

83/110/22 |

110/160/30 |

83/110*2/30 |

|

Weight (kg) |

3300 |

4200 |

5500 |

6500 |

8000 |

Product detail pictures:

Related Product Guide:

we can easily offer you high-quality products and solutions, competitive rate and very best shopper support. Our destination is "You come here with difficulty and we give you a smile to take away" for OEM Customized Recycling Machines Price - SRL-W Series Horizontal Mixing Unit – Polestar , The product will supply to all over the world, such as: Jordan, Salt Lake City, Slovakia, With strong technical strength and advanced production equipment, and SMS people purposefully , qualified, dedicated spirit of enterprise. Enterprises took the lead through the ISO 9001:2008 international quality management system certification, CE certification EU ; CCC.SGS.CQC other related product certification. We look forward to reactivating our company connection.

Cooperate with you every time is very successful, very happy. Hope that we can have more cooperation!

Products categories

Want To Add Sky To Your Design?

Contact us today for a design consultation.