When it comes to Vacuum calibrator, investing in high-quality materials and design offers significant benefits that impact both performance and cost-efficiency. For companies working with polyethylene (PE) piping, reliable cooling tanks are essential to maintain product integrity during manufacturing. This article explores why quality matters inVacuum calibrator and what factors to consider for optimal performance.

1. Enhanced Durability and Lifespan

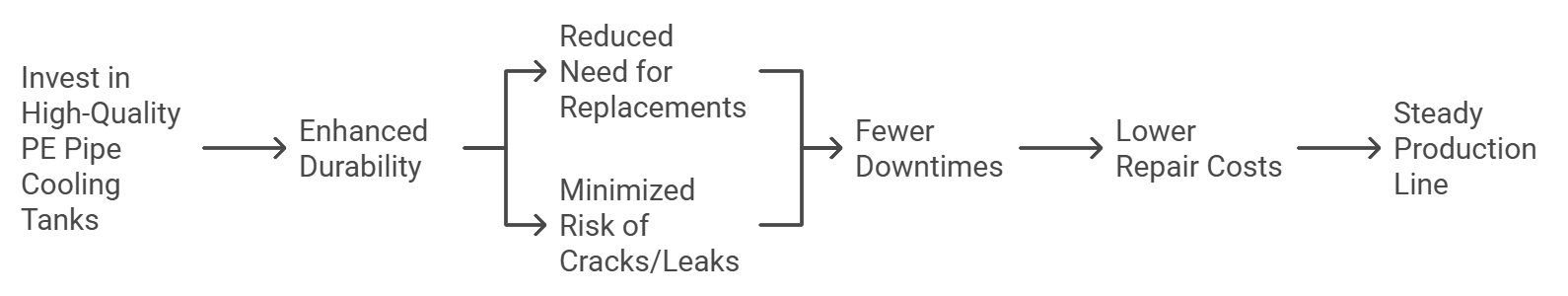

High-qualityVacuum calibrator are built to withstand rigorous conditions, including constant exposure to water and temperature fluctuations. Durable tanks reduce the need for frequent replacements and minimize the risk of cracks or leaks. By investing in a tank that’s built for longevity, manufacturers can experience fewer downtimes, lower repair costs, and a steady production line.

2. Superior Efficiency and Consistency

A high-quality PE pipe cooling tank is designed to maintain consistent temperature control, which is essential for achieving the desired mechanical properties in PE pipes. Efficient cooling minimizes distortion and shrinkage, helping manufacturers produce pipes with accurate dimensions and high tensile strength. This consistency directly impacts the final product’s reliability, ensuring customers receive high-performing, dependable pipes for various applications.

3. Reduced Energy Consumption

Quality cooling tanks often incorporate efficient design elements that reduce energy consumption. For instance, well-insulated tanks maintain stable temperatures without requiring excessive power input, lowering overall energy costs. Additionally, when the cooling process is optimized, it can shorten production time, leading to cost savings and a smaller environmental footprint.

4. Lower Maintenance Requirements

Low-quality cooling tanks often require frequent maintenance due to premature wear and tear. On the other hand, high-quality tanks come with robust components and resistant materials that minimize the frequency of repairs. Reduced maintenance not only saves on operational costs but also allows companies to focus resources on growth and innovation.

5. Improved Safety Standards

Safety is paramount in industrial settings, and a high-quality PE pipe cooling tank is designed with safety in mind. Tanks manufactured with premium materials are less likely to fail, protecting workers from potential hazards related to leaks or temperature issues. Moreover, these tanks adhere to strict quality standards, ensuring peace of mind and a safe working environment.

6. Value for Long-term Investment

Although premiumVacuum calibrator may come with a higher initial investment, the long-term benefits outweigh the cost. Enhanced durability, reduced operational costs, and minimized downtime collectively contribute to better financial returns over time. This approach allows companies to allocate resources more effectively, making high-quality tanks a wise choice for sustainable growth.

Conclusion

Investing in a high-quality PE pipe cooling tank is essential for companies seeking durability, efficiency, and cost savings. By understanding the advantages of a reliable cooling system, businesses can optimize their manufacturing processes, improve safety standards, and provide superior products to customers.

Post time: Oct-30-2024