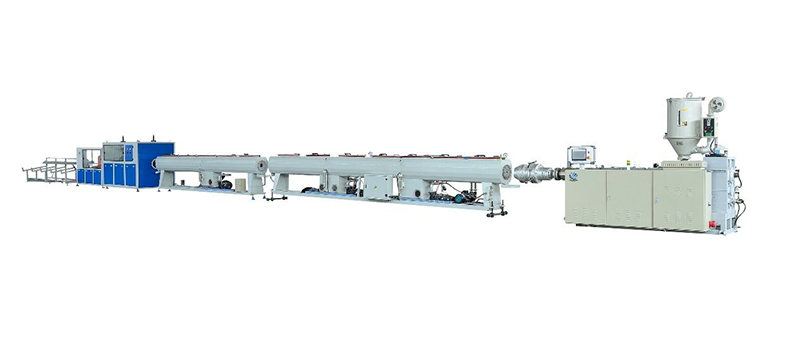

Introduction: In modern industrial and construction domains, plastic pipes have become indispensable components for conveying fluids and facilitating drainage solutions. Plastic pipe extrusion machines play an increasingly pivotal role in producing efficient and reliable pipeline solutions across diverse industries.

- Urban Infrastructure Development: Plastic pipes are crucial components in urban infrastructure projects. Pipes produced by plastic pipe extrusion machines, such as drainage and water supply pipes, boast corrosion resistance and exceptional durability, adapting well to varying soil and environmental conditions. These pipes are instrumental in maintaining smooth and safe urban drainage and water supply systems.

- Agriculture Sector: Plastic pipes find extensive use in agricultural irrigation systems and greenhouse cultivation. Drip irrigation and spray irrigation pipelines manufactured by plastic pipe extrusion machines enable precise water delivery, ensuring efficient irrigation and minimizing water wastage. Additionally, the durability of plastic pipes helps them withstand chemical agents and natural elements present in agricultural environments.

- Construction and Building Structures: Plastic pipes are widely employed in construction for HVAC systems, electrical conduit protection, indoor and outdoor drainage systems, and more. Pipes produced through plastic pipe extrusion machines offer not only durability but also flexibility in meeting varied architectural designs and structural needs. Their lightweight characteristics further streamline installation, reducing construction costs and time.

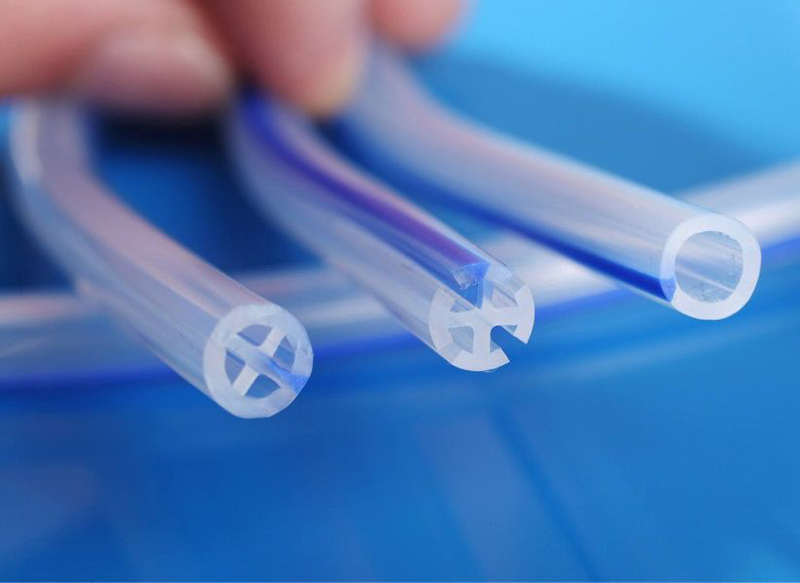

- Medical and Pharmaceutical Industries: High-quality plastic pipes are essential for transporting liquid medications and preparing bioreactors in the medical and pharmaceutical sectors. The smooth interior surfaces of pipes produced by plastic pipe extrusion machines help mitigate risks of residual drug presence and cross-contamination, ensuring a sterile and efficient production process.

- Environmental Sustainability and Recycling: As environmental awareness grows, the recycling of plastic pipes gains prominence. Plastic pipe extrusion machines can utilize recycled plastic materials to manufacture reliable pipe products, reducing the demand for virgin plastics and contributing to sustainable development.

Conclusion: In summary, plastic pipe extrusion machines have significant applications in urban infrastructure, agriculture, construction, medical/pharmaceutical, and environmental sectors. With ongoing technological innovation and advancement, these machines will continue to provide efficient and innovative solutions for various industries, driving progress and development.

Post time: Aug-28-2023