Manufacturer for Waste Plastic Pelletizing Machine - Plastic PE PP Bridge Cable Casing Pipe Making Machine – Polestar

Manufacturer for Waste Plastic Pelletizing Machine - Plastic PE PP Bridge Cable Casing Pipe Making Machine – Polestar Detail:

Description

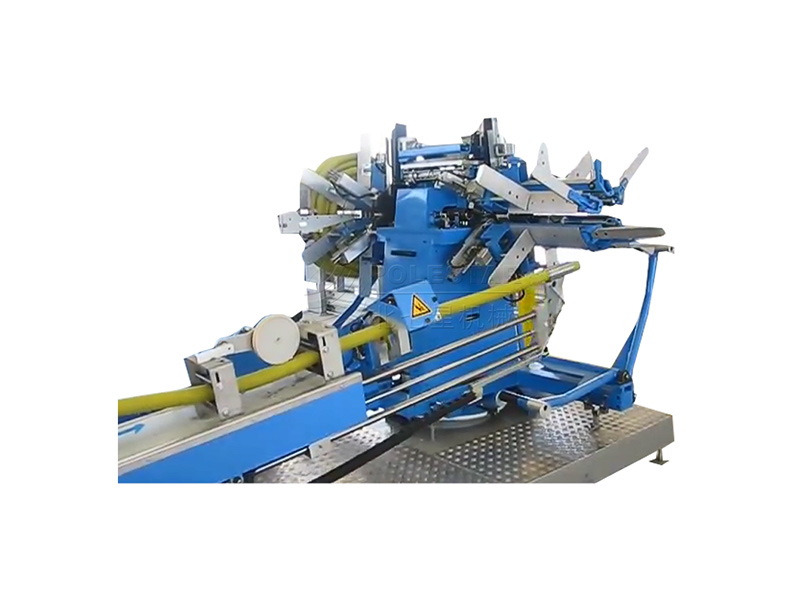

This vacuum calibrating bench barrels being made of stainless steel.Is divided into two sections, front and back end is vacuum cooling and spray cooling.Stainless steel ball float water level regulation, the structure is simple and practical. Nozzle materials for ABS engineering plastics. Rack 3 d adjustable, before and after the mobile adopts cycloidal reducer drive, up and down and around adopts screw pair of regulation.Barrel body with wheel mechanism; Which can effectively prevent sagging phenomenon.

Application

The vacuum calibrating tank is a necessary part in pipe production line.

It can help pipes form stable and fast.

The vacuum calibrating tank is of high quality and easy operation.

We have many diffierent types of vacuum calibrating tank for customers to make a proper choice.

Vacuum Tank

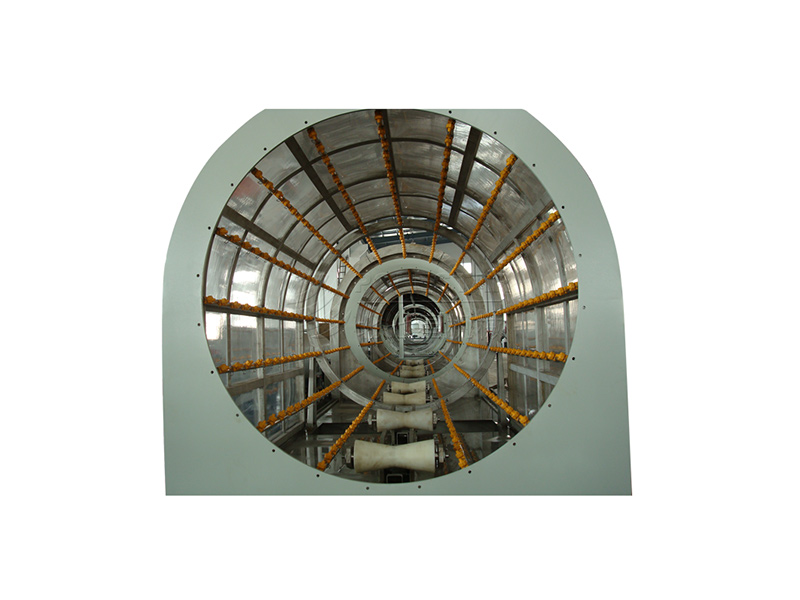

Vacuum tank is used to shape and cool pipe, so as to reach standard pipe size. We use double-chamber structure. First chamber is in short length, to ensure very strong cooling and vacuum function. As calibrator is placed in the front of first chamber and pipe shape is formed mainly by calibrator, this design can ensure quick and better forming and cooling of pipe.

Strong Cooling for Calibrator

Better Support for Pipe

Flowmeter–Accurate control for calibrator’s water supplement.

Pressure Protection System–Automatically and manually adjust.

Water Level Control Point–contact floating ball for water level control.

Puissant Precool Ring–Puissant precool ring set in the entrance of vacuum tank, brings good cooling effect when pipes move into the vacuum tank.

S.S. Semicircle Sliding Plate Pipe supporting adopts S.S. semicircle sliding plate, high intensity supporting.

Turbine Screw Lifter 4 directions convenient adjustment, turbine lifter adjustment for up & down, pulley adjustment for left & right.

Temperature Control Drainage Danfoss expansion valve temperature-controlled drainage.

Water Inflow control Both automatically and manually for appropriate water level.

Product detail pictures:

Related Product Guide:

That has a sound business enterprise credit rating, exceptional after-sales provider and modern producing facilities, we now have earned an superb standing amongst our buyers across the world for Manufacturer for Waste Plastic Pelletizing Machine - Plastic PE PP Bridge Cable Casing Pipe Making Machine – Polestar , The product will supply to all over the world, such as: Netherlands, Irish, Argentina, With well educated, innovative and energetic staff, we are responsible for all elements of research, design, manufacture, sale and distribution. By studying and developing new techniques, we are not only following but also leading fashion industry. We listen attentively to the feedback from our customers and provide instant replies. You will instantly feel our professional and attentive service.

The company can keep up with the changes in this industry market, product updates fast and the price is cheap, this is our second cooperation, it's good.

Products categories

Want To Add Sky To Your Design?

Contact us today for a design consultation.