Manufacturer for Pipe Extruder - Waste PET Bottles Washing Machine – Polestar

Manufacturer for Pipe Extruder - Waste PET Bottles Washing Machine – Polestar Detail:

Description

PoleStar plastic reycling machine is designed for recycling daily-use plastic products. Plastic recycing is important for enviroment. We are professional in manufacturing plastic recycling machine. Plastic recycling plant includes grading, crushing, washing, drying and so on.

Plastic recycling machine is researched, design and manufactured by our company, integration of Europe technology, plastic recycling machine has features as high efficiency, working stable, low humidity content(less than 1%). We use good quality on our washing recycling machine(SUS-304,more than 3mm thickness) ensures whole recycling equipment long service life time.

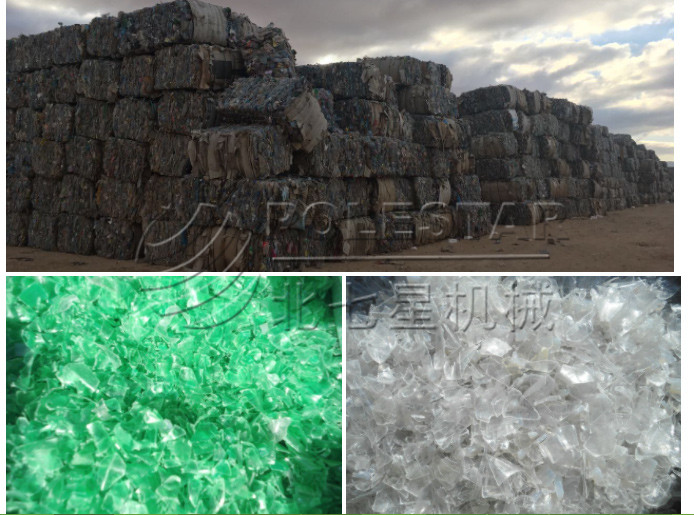

PET bottle recycling machine is machine to recycle plastic pet bottles, which get rid of PE/ PP label, cap, oil, garbage, protect the environment, avoid white pollution.

PET bottle recycling plant is composed of separator, crusher, cold & hot washing system, dewatering, drying, packing system, etc. This pet bottle flakes recycling machine line takes compacted bales of PET bottles and turns them into clean, contaminant-free PET flakes that can be used in producing polyester staple fiber or pelletized into granules for use in manufacturing other PET products. Our pet bottle washing machine is high automatic and efficient. Our pet bottle washing machine is welcomed by customers also pet bottle recycling machine price is good competitive.

Final Product

Surface moisture: 1%

PVC content: max. 500 ppm(According to your worker sorting)

Glue content: max. 4.000 ppm (Flakes included)

Label content: max. 500 ppm(According to your worker sorting)

HDPE / PP content: max. 500 ppm

PET dust: max. 0.1 %

Metal content: max. 50 ppm

Technical Data

|

Model |

Output (kg/h) |

Power Consumption (kW/h) |

Steam (kg/h) |

Detergent (kg/h) |

Water (t/h) |

Installed Power (kW/h) |

Space (m2) |

| PET-500 |

500 |

180 |

500 |

10 |

0.7 |

200 |

700 |

|

PET-1000 |

1000 |

170 |

600 |

14 |

1.5 |

395 |

800 |

|

PET-2000 |

2000 |

340 |

1000 |

18 |

3 |

430 |

1200 |

|

PET-3000 |

3000 |

460 |

2000 |

28 |

4.5 |

590 |

1500 |

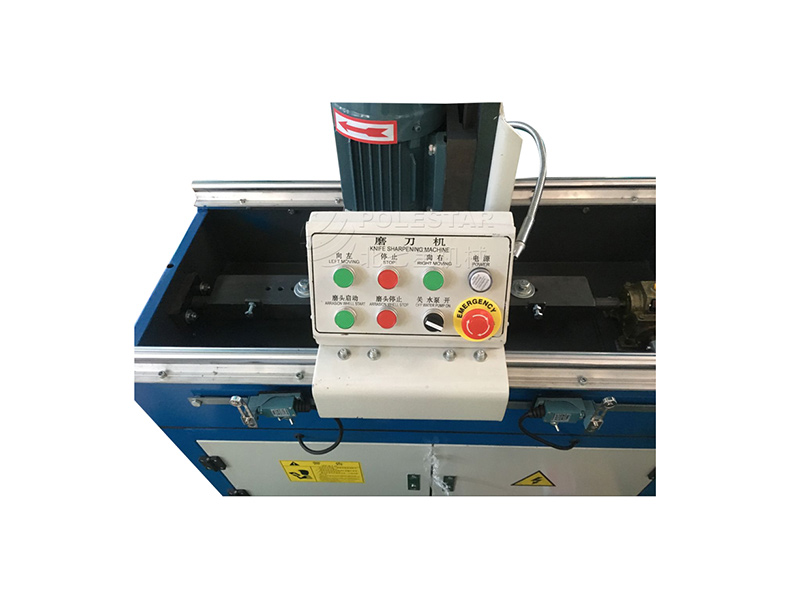

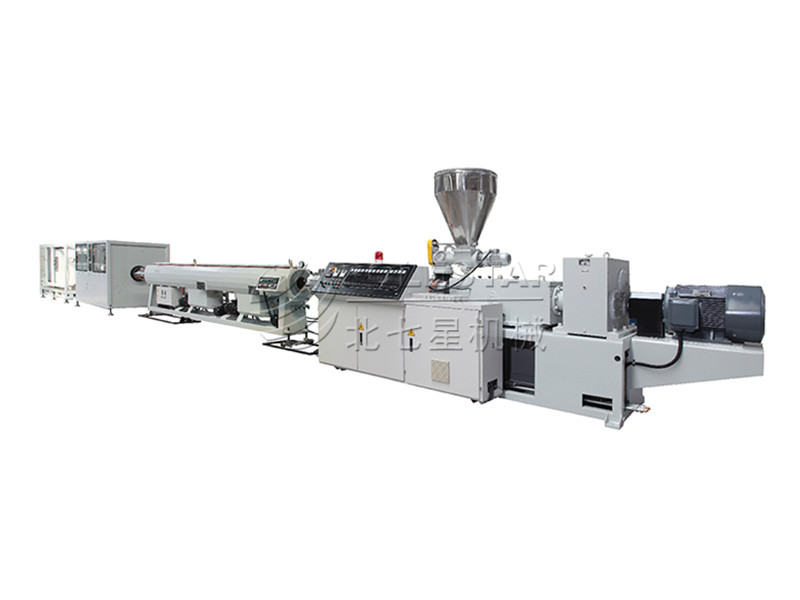

Product detail pictures:

Related Product Guide:

We usually perform being a tangible workforce making sure that we will give you the most beneficial excellent plus the finest selling price for Manufacturer for Pipe Extruder - Waste PET Bottles Washing Machine – Polestar , The product will supply to all over the world, such as: Hamburg, Niger, Armenia, We have now 48 provincial agencies in the country. We also have stable cooperation with several international trading companies. They place order with us and export solutions to other countries. We expect to cooperate with you to develop a larger market.

Goods just received, we are very satisfied, a very good supplier, hope to make persistent efforts to do better.

Products categories

Want To Add Sky To Your Design?

Contact us today for a design consultation.