Leading Manufacturer for Plastic Material Mixer Machine - High Efficient PET Granulating Machine – Polestar

Leading Manufacturer for Plastic Material Mixer Machine - High Efficient PET Granulating Machine – Polestar Detail:

Characteristics

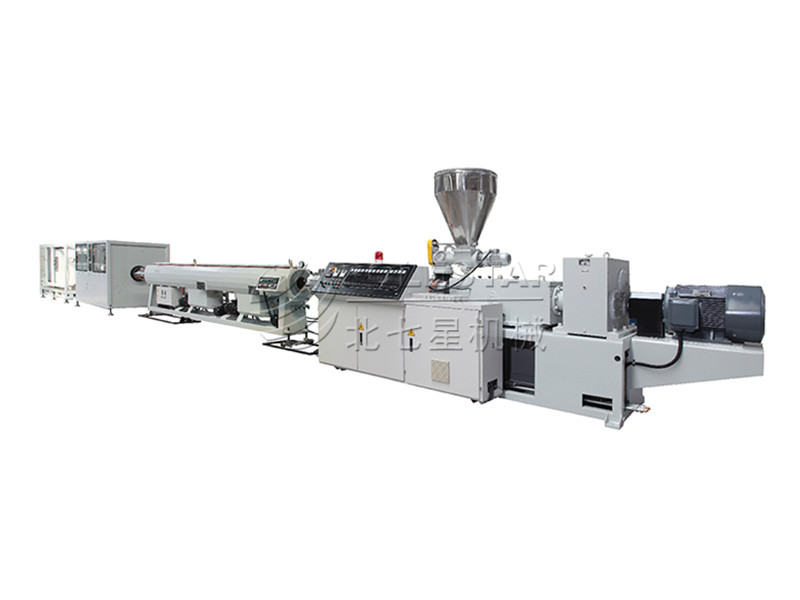

The PET pelletizer is mainly consisted by the following equipment: extruder, hydraulic screen changer, strand cutting mold, cooling conveyor, dryer, cutter, fan blowing system (feeding and drying system), etc. Use parallel twin screw extruder to have accurate temperature control, high output with lower power consumption.

Application

The pet pelletizing machine is is used to make PET plastic flakes into pellet or granule.Twin screw extruder recycling & pelletizing system are applied to the waste materials, which needs high processing performance of melting, volatilization, filtering etc.

Process Flow

Screw feeder ( OPTIONAL)→ Force feeder→ Parallel twin screw extruder →Hydraulic filter exchanger→ Mould head →water cooling tank →Plastic standard cutter→ Finished product packing.

Detailed Description of Each Item

1. Screw Feeder: convey Plastic scraps into the main machine.

2. Force feeder: feed material to extruder with a designed speed, the speed can be adjusted.

3. Parallel twin screw extruder: plasticizing material and exhausting gas.

4. High-speed Net exchanging system and Die-head: filter material impurity, to make production more stable.

5. Water tank: cooling the PET noodles.

6. Plastic standard cutter: cut the PET noodles into granuels.

Competitive Advantage

1. Automatic PLC control

2. With individual temperature control

3. Convenient operation & Stable performance

4. Highly efficient, environmental protection and energy saving

Technical Data

|

Extruder |

TSK35 |

TSK50 |

TSK60 |

TSK65 |

TSK75 |

TSK95 |

|

L/D(mm) |

24-56 |

24-56 |

24-56 |

24-56 |

24-56 |

24-56 |

|

Max Speed(rpm) |

600 |

500 |

300-500 |

400-500 |

400-500 |

300-400 |

|

Motor Power(kw) |

11-18.5 |

22-37 |

37-55 |

45-75 |

90-160 |

185-250 |

|

Heater Power(kw) |

16 |

24 |

30 |

34 |

45 |

60 |

|

Max Output(kg/h) |

20-80 |

50-200 |

80-300 |

100-350 |

200-500 |

700-1200 |

Product detail pictures:

Related Product Guide:

We often stay with the principle "Quality Very first, Prestige Supreme". We have been fully committed to supplying our consumers with competitively priced high-quality goods, prompt delivery and skilled provider for Leading Manufacturer for Plastic Material Mixer Machine - High Efficient PET Granulating Machine – Polestar , The product will supply to all over the world, such as: Austria, Yemen, Johannesburg, If you are for any reason unsure which product to select, do not hesitate to contact us and we are going to be delighted to advise and assist you. This way we are going to be providing you with all the knowledge needed to make the best choice. Our company strictly follows "Survive by good quality, Develop by keeping good credit. " operation policy. Welcome all the clients old and new to visit our company and talk about the business. We have been looking for more and more customers to create the glorious future.

The sales manager is very patient, we communicated about three days before we decided to cooperate, finally, we are very satisfied with this cooperation!

Products categories

Want To Add Sky To Your Design?

Contact us today for a design consultation.