Hot sale Pvc Pipe Manufacturing Machine - Automatic Pvc Pipe Belling Machine – Polestar

Hot sale Pvc Pipe Manufacturing Machine - Automatic Pvc Pipe Belling Machine – Polestar Detail:

Description

1. SGK series FullAuto Pipe Belling machine with hauling device and program interface concerned is used with extruding machine. It is also used solitarily.

2. While expanding pipes, the machine adopts translation. The action is steady and correct. It does not damage pipes.

3. The machine adopts electric heating type. Each oven is equipped with heating core. The shaping method adopts expandingend shaping. The size of pipe mouth is correct. On its panel, there is a transfer switch for belling solvent type socket (Straight port) and seal loop type pipe socket( R type). The choice of expanding pipe types is very convenient.

4. The technological adaptability is strong. All the key electric control elements are imported.

Applications

SGK Series pipe belling machines include automatic pipe beling machine and semi-automatic pipe belling machine. It worked with mould for pipe belling, which can be linked with plastic pipe production line and also can be used separately.

Technical Data

| Model | SGKS63 | SGK250 | SGK315 | SGK400 | SGK710 | SGKB250 |

| Pipe diameter(mm) | Φ20-Φ63 | Φ63-Φ250 | Φ110-Φ315 | Φ160-Φ400 | Φ315-Φ710 | Φ63-Φ250 |

| Belling Method | Double pipe | Vacuum | ||||

| Cooling Method | Wind or water | Water cooling | ||||

| Heating power(kW) | 4 | 4 | 7.2 | 15.6 | 25.4 | 25.4 |

| Total Power(kW) | 5.53 | 10.1 | 12.1 | 22 | 36.2 | 10.1 |

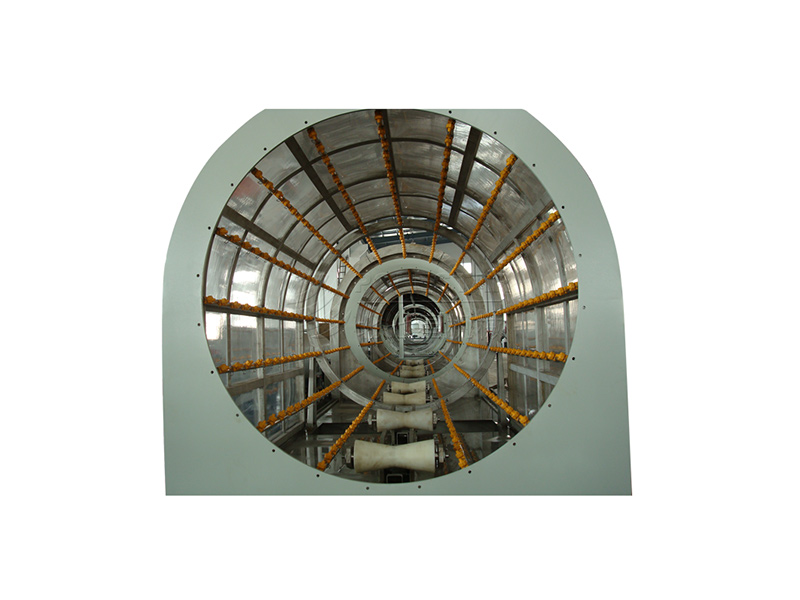

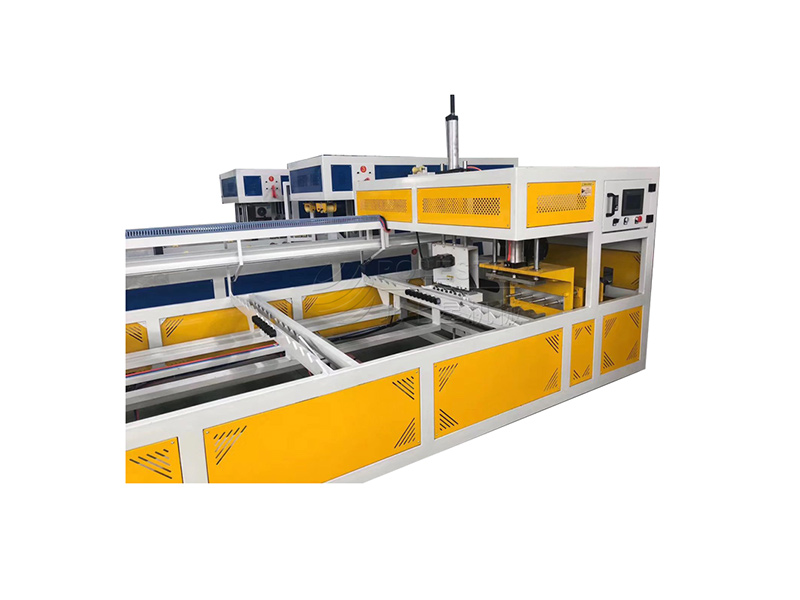

Product detail pictures:

Related Product Guide:

All we do is always involved with our tenet " Consumer initial, Trust first, devoting within the food stuff packaging and environmental defense for Hot sale Pvc Pipe Manufacturing Machine - Automatic Pvc Pipe Belling Machine – Polestar , The product will supply to all over the world, such as: Anguilla, United States, Southampton, Taking the core concept of "to be the Responsible". We will redound up on society for high quality products and good service. We will initiative to participate in international competition to be a first- class manufacturer of this product in the world.

This supplier's raw material quality is stable and reliable, has always been in accordance with the requirements of our company to provide the goods that quality meet our requirements.

Products categories

Want To Add Sky To Your Design?

Contact us today for a design consultation.