High Quality Plastic Recycling Extruder - PE LDPE LLDPE PP(Disc Type) Pulverizer Machine – Polestar

High Quality Plastic Recycling Extruder - PE LDPE LLDPE PP(Disc Type) Pulverizer Machine – Polestar Detail:

Description

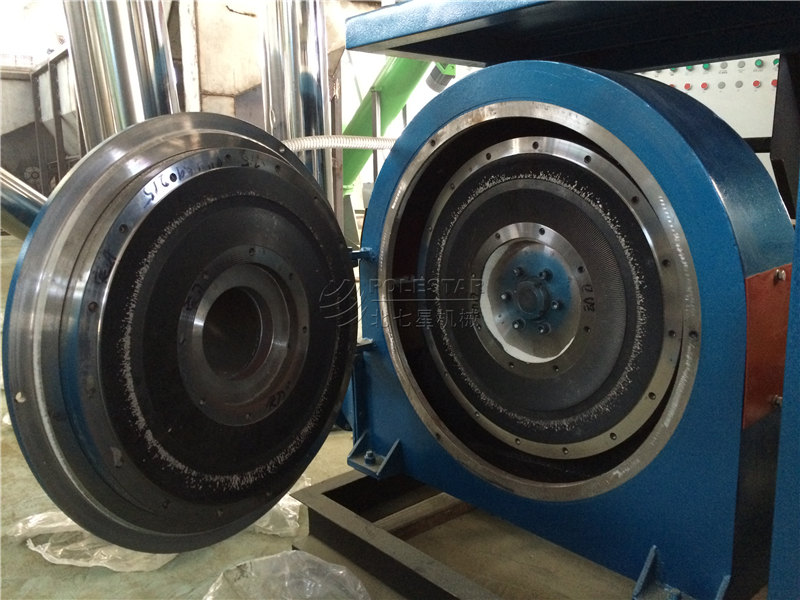

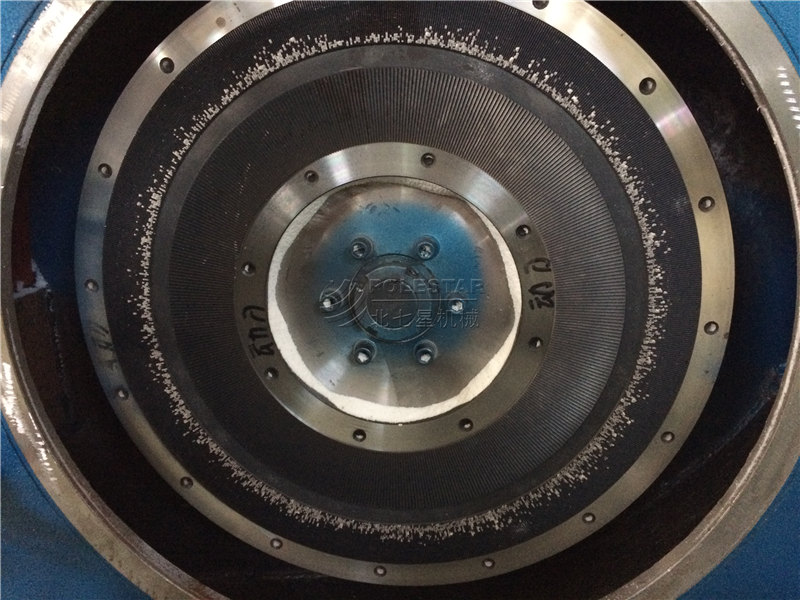

The disc pulverizer machine are available with disc diameter from 300 to 800 mm. These plastic pulverizer are high speed, precision grinders for the processing of medium hard, impact resistant and friable materials. The material to be pulverized is introduced through the centre of a vertically fixed grinding disc which is mounted concentrically with an identical high speed rotating disc. Centrifugal force carries the material through the grinding area and the resulting powder is collected with a blower and cyclone system. Plastic pulverizer machine / plastic milling machine can be equipped with one piece grinding discs or grinding segments.

The plastic milling machine is mainly composed of electric motor, disc type blade, feeding fan, vibrating sieve, dust removing system, etc.

According to the customer’s needs, you can choose some accessories, such as converter, vacuum loader, screw loader, magnetic net, metal separator, chiller, pulse dust collector, metering and weighing packaging machine, etc.

Advantages

1. Low power consumption, high capacity

2. Simple structure and easy installation.

3. Host with the wind ,water circulation cooling system.

4. This pulverizer machine for plastic can deal with PE, LLDPE, LDPE, ABS, EVA plastic etc.

5. Convenient and easy to adjust the grinding disc blades

6. With water cycle and wind cooling, the machine can be applied into processing heat sensitive material evenly and quickly.

7. Both the board and the cutting blade are made of abrasion-resistant steel, with good performance after heat treatment.

8. This plastic milling machine is completely air proof and without any dust leakage

9. The vibration screen mesh is adjustable (10-100 mesh).

Technical Data

| Model | MP-400 | MP-500 | MP-600 | MP-800 |

| Diameter of milling chamber(mm) | 350 | 500 | 600 | 800 |

| Motor power(kw) | 22-30 | 37-45 | 55 | 75 |

| Cooling | Water cooling + natural cooling | |||

| Air Blower power(kw) | 3 | 4 | 5.5 | 7.5 |

| Fineness of LDPE power | 30 to 100mm adjustable | |||

| Output of pulverizer(kg/h) | 100-120 | 150-200 | 250-300 | 400 |

| Dimension (mm) | 1800×1600×3800 | 1900×1700×3900 | 1900×1500×3000 | 2300×1900×4100 |

| Weight (kg) | 1300 | 1600 | 1500 | 3200 |

Product detail pictures:

Related Product Guide:

Our target is always to satisfy our customers by offering golden support, superior value and high quality for High Quality Plastic Recycling Extruder - PE LDPE LLDPE PP(Disc Type) Pulverizer Machine – Polestar , The product will supply to all over the world, such as: Israel, Muscat, Estonia, We focus on providing service for our clients as a key element in strengthening our long-term relationships. Our continual availability of high grade products in combination with our excellent pre-sale and after-sales service ensures strong competitiveness in an increasingly globalized market. We are willing to cooperate with business friends from at home and abroad and create a great future together.

Product variety is complete, good quality and inexpensive, the delivery is fast and transport is security, very good, we are happy to cooperate with a reputable company!

Products categories

Want To Add Sky To Your Design?

Contact us today for a design consultation.