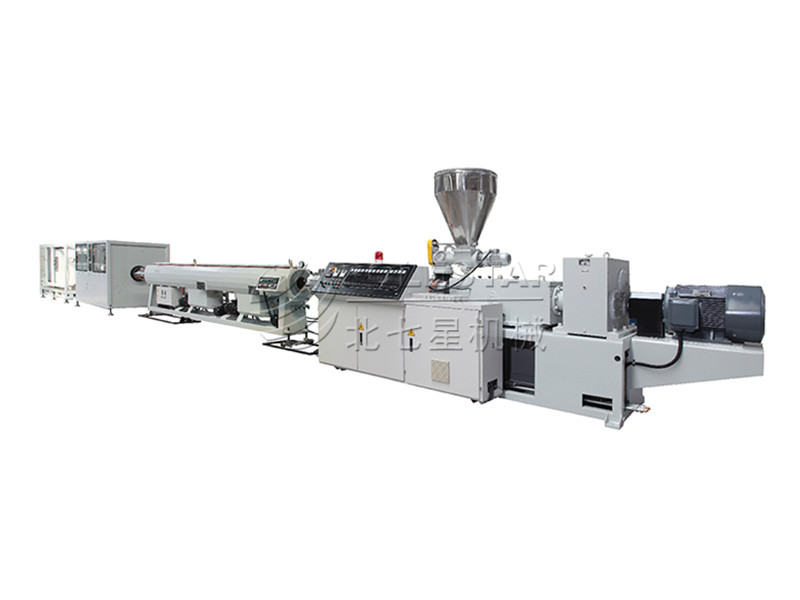

Good Quality Drum Crusher - High Precision PVC Pipe Mould – Polestar

Good Quality Drum Crusher - High Precision PVC Pipe Mould – Polestar Detail:

Description

Plastic extrusion molds are made of high quality alloy steel, the quenched and tempered treatment, flow surface polishing chromium plating processing.Sizing material for copper alloy;Range of pipe:: 20,32,40,50,63,75,90,110,125,150,200,225,250,315,400.etc. Have Basic mould,mouth mould, core mould, have mould turn over car.

High Quality Material

Competitive Advantage

Characteristics

| Specification | GF-125 | GF-160 | GF-250 | GF-500 | GF-630 |

| Max. pipe diameter(mm) | 125 | 160 | 250 | 500 | 630 |

| Total power of auxiliary machine (kw) | 13 | 14 | 19 | 27.5 | 35 |

| Cooling water consumption (m3/h) | 3 | 6 | 6 | 9 | 12 |

| Compressed air pressure (Mpa) | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 |

Plastic Extrusion Molds

Moving Device of Die Head

For big size die head, moving device can move die head forward and back, also adjust the height of die head. Operation is fast and easy.

Die Head Rotary Device

For big size die head with rotary device, die head can rotate by 90 degree. When changing bush, mandrel, die head will turn 90 degree. Can use crane to lift and change bush and mandrel. This way is very convenient.

CNC Processing

Every part of extrusion die head is processed by CNC to ensure precision.

High Quality Material

Apply high quality material for extrusion die head. Die head has high strength and will not deform during long time use under high temperature condition.

Product detail pictures:

Related Product Guide:

We're commitment to offer you the aggressive cost ,superb products and solutions top quality, too as fast delivery for Good Quality Drum Crusher - High Precision PVC Pipe Mould – Polestar , The product will supply to all over the world, such as: European, Cologne, Canada, We take measure at any expense to achieve essentially the most up-to-date equipment and approaches. The packing of nominated brand is our a further distinguishing feature. The items to assure years of trouble-free service has attracted a great deal customers. The solutions are obtainable in improved designs and richer assortment, they're created scientifically of purely raw supplies. It readily available in a variety of designs and specifications for your selection. The most recent kinds are a great deal better than the preceding one particular and they are quite popular with lots of prospects.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.

Products categories

Want To Add Sky To Your Design?

Contact us today for a design consultation.