Factory selling Bottle Grinder - EVA TPR TPU Plastic Underwater Granulation Line – Polestar

Factory selling Bottle Grinder - EVA TPR TPU Plastic Underwater Granulation Line – Polestar Detail:

Description

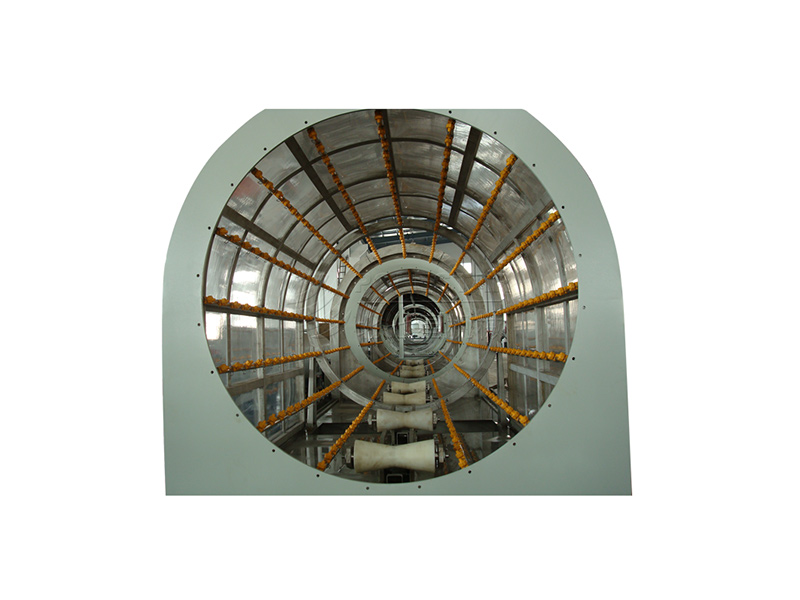

This granulation line is composed of Feeding system(Screw metering feeder and Side feeding system ) , twin screw extruder ,Water cooling system, Electronical control system and under water pelletizing system. Raw material : PP, HDPE, LDPE, LLDPE, TPV, EVA, ABS, PA and PS, etc.

Application

Under water pelletizing line is applied in PET+PE, PE, PP waste flakes granulation field.Through extrusion, cutting and dry process, the waste bottle will become to be pellets.The pellets are widely used in plastic industry, like sheet, and profile production.

From feeding system to final products, we can design and work out a complete system to satisfy all of your production requirements.We will provide you with a pelletizing system in good quality and price as per your requirements.

Competitive Advantage

1. Superhard alloy die head (made by our company ,guarantee serviceability two years,hardness can reach HRC88-90,superior to BKG company)

2. Wearproof special alloy blade(made by our company,lift time at least one year,hardness reach HRC70-75,superior to BKG company)

3. Special die head temperature control device (made by our company,non-contact induction heating, heat up fast ,superior to BKG company and other domestic manufacturers’ electric heating rod heating)

4. Pneumatic control,automatically adjustable eager knife system(The original patent products of our company,superior to other domestic manufacturers’ spring manual pressure regulating system)

5. One-click boot(easy operation)

Polestar Machinery a professional factory for manufacturing series waste plastic recycling equipment (PET bottle recycling; PE/PP film,bags recycling, HDPE bottle /PP barrel recycling, and PP PE film pelletizing ,PP PE flakes pelletizing, PP/PE/PVC corrugated pipe extruder etc). If you want more details of our PET bottle washing machine/waste plastic recycling machine/ plastic pelletizing line, please do not hesitate to let me know! Welcome to our factory!

Technical Data

| Model | TSSK-30 | TSSK-35 | TSSK-50 | TSSK-65 | TSSK-75 | TSSK-95 |

| Screw diameter(mm ) | 28.5 | 33.2 | 48.1 | 63 | 72 | 92 |

| ROtary speed(rpm) | 400 | 400/600 | 500/600 | 400/500 | 400/500 | 400/500 |

| Main motor power(kw) | 11 | 11/15 | 37/45 | 55/75 | 90/110 | 220/250 |

| L/D(L/D) | 28-48 | 32-48 | 32-48 | 32-48 | 32-48 | 32-40 |

| Capacity(kg/hr) | 5-30 | 10-80 | 20-150 | 100-300 | 300-600 | 700-1000 |

Product detail pictures:

Related Product Guide:

We always think and practice corresponding to the change of circumstance, and grow up. We aim at the achievement of a richer mind and body and the living for Factory selling Bottle Grinder - EVA TPR TPU Plastic Underwater Granulation Line – Polestar , The product will supply to all over the world, such as: Palestine, Czech, United States, We warmly welcome domestic and overseas customers to visit our company and have business talk. Our company always insists on the principle of "good quality, reasonable price, the first-class service". We have been willing to build long-term, friendly and mutually beneficial cooperation with you.

In general, we are satisfied with all aspects, cheap, high-quality, fast delivery and good procuct style, we will have follow-up cooperation!

Products categories

Want To Add Sky To Your Design?

Contact us today for a design consultation.