factory Outlets for Waste Plastic Shredder - High Quality Strong Plastic Crusher Machine – Polestar

factory Outlets for Waste Plastic Shredder - High Quality Strong Plastic Crusher Machine – Polestar Detail:

Description

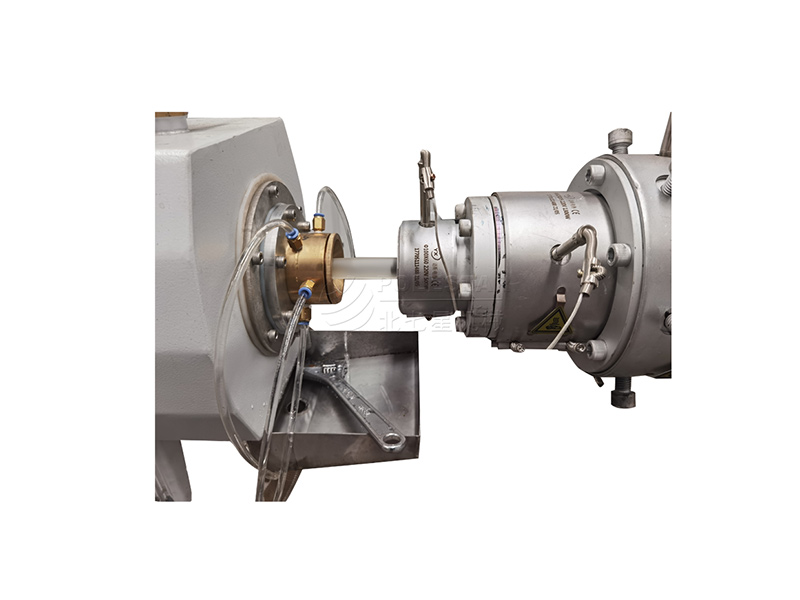

Plastic crusher machine mainly consists of motor, rotary shaft, moving knives, fixed knives, screen mesh, frame, body and discharging door. Fixed knives are installed on the frame, and equipped with a plastic rebound device. Rotary shaft is embedded in thirty removable blades, when using blunt can be removed to separate grinding, rotate to be helical cutting edge. So the blade has long life, stable work and strong crushing capacity. Sometimes when equipped with a winding conveying device, the discharging system could be much convenient and realize bagging automatically. Plastic grinder machine / plastic crusher machine is crush plastic bottles, plastic films, bags, fishing nets, fabrics etc. Raw material will be crushed into 10mm-35mm (customized) with different sizes of screen meshes.

Features

1. Crusher machine can choose different blade and shaft structure to meet different material. Crushed material is very small, could be directly used for pelletizing or other recycling;

2. Motor and shaft is directly connected by belt, ensuing high rotating speed and efficiency;

3. Whole machine is an integrated sealing structure, fame is specially processed, can effectively reduce vibration and noise during production.

Technical Data

| Model | BX400 | BX500 | BX600 | BX700 | BX800 | BX900 | BX1000 |

| Motor power (kW) | 7.5 | 11 | 15 | 22 | 30 | 37 | 45 |

| Fixed blade qty. (pcs) | 2 | 2 | 4 | 4 | 4 | 4 | 4 |

| Moving blade qty. (pcs) | 5 | 15 | 18 | 21 | 24 | 27 | 30 |

| Capacity (kg/h) | 100-150 | 200-250 | 300-350 | 450-500 | 600-700 | 700-800 | 800-900 |

| Feeding mouth (mm) | 450*350 | 550*450 | 650*450 | 750*500 | 850*600 | 950*700 | 1050*800 |

Product detail pictures:

Related Product Guide:

Our primary purpose is to give our shoppers a serious and responsible company relationship, giving personalized attention to all of them for factory Outlets for Waste Plastic Shredder - High Quality Strong Plastic Crusher Machine – Polestar , The product will supply to all over the world, such as: Bhutan, Ecuador, Croatia, Our company will continue to serve customers with best quality, competitive price and timely delivery & the best payment term! We sincerely welcome friends from all over the world to visit& cooperate with us and enlarge our business. If you are interested in our products, please do not hesitate to contact us, we will be happy to provide you with further information!

Although we are a small company, we are also respected. Reliable quality, sincere service and good credit, we are honored to be able to work with you!

Products categories

Want To Add Sky To Your Design?

Contact us today for a design consultation.