Factory Outlets Double Station Pipe Winder - Stainless Steel Vertical Plastic Granules Mixer – Polestar

Factory Outlets Double Station Pipe Winder - Stainless Steel Vertical Plastic Granules Mixer – Polestar Detail:

Description

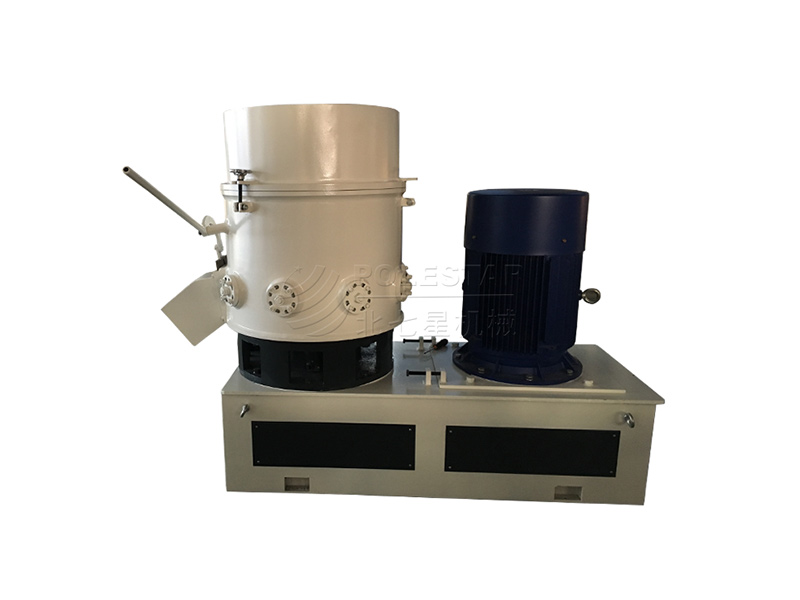

Vertical plastic mixer is an ideal plastic mixer machine for mixing plastics, with the rapid rotation of the screw, the raw materials are lifted from the bottom of the barrel from the center to the top, and then scattered to the bottom by umbrella flying, so that the raw materials can be stirred up and down in the barrel, and a large number of raw materials can be evenly mixed in a short time.

Advantages

1.The plastic mixer machine is composed of mixing tank body, mixing tank cover, mixer, support, transmission device, shaft seal device, etc., and can be equipped with heating device or cooling device according to the process requirements; in the mixing process, the feeding control, discharge control, mixing control and other manual automatic control are available, which fully embodies the standardized and humanized design.

2.Mixing tank body, mixing tank cover, mixer, shaft seal, etc., can be made of carbon steel or stainless steel according to different process requirements. .

3.The mixing tank body and the mixing tank cover can be sealed with flanges or welded. The process pipe holes such as feeding, discharging, observation, temperature measurement, pressure measurement, steam fraction and safe emptying can be carried out according to the process requirements.

4.The upper part of the mixing tank cover is equipped with a transmission device (motor or reducer), and the agitator in the mixing tank is driven by the drive shaft. .

5.The shaft seal device can be in many forms, such as machine seal or packing, labyrinth seal and so on (determined according to the needs of users).

Technical Data

|

Model |

Power(kw) |

Capacity(KG) |

Dimension(mm) |

Rotating Speed |

Heating Power |

Blower |

|

BQX-500L |

2.2 |

500 |

1170*1480*2425 |

300 |

12 |

0.34 |

|

BQX-1000L |

3 |

1000 |

1385*1800*3026 |

300 |

18 |

1 |

|

BQX-2000L |

4 |

2000 |

1680*2030*3650 |

300 |

30 |

1.5 |

|

BQX-3000L |

5.5 |

3000 |

2130*2130*3675 |

300 |

38 |

2.2 |

|

BQX-5000L |

7.5 |

5000 |

3500*3500*3675 |

300 |

38 |

2.2 |

Product detail pictures:

Related Product Guide:

We take pleasure in an extremely fantastic standing among the our prospects for our great product top quality, competitive cost and the finest support for Factory Outlets Double Station Pipe Winder - Stainless Steel Vertical Plastic Granules Mixer – Polestar , The product will supply to all over the world, such as: Malawi, Provence, Montpellier, Our objective is "to supply first step products and best service for our customers, thus we are sure you must have a margin benefit through cooperating with us". If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future.

The company keeps to the operation concept "scientific management, high quality and efficiency primacy, customer supreme", we have always maintained business cooperation. Work with you,we feel easy!

Products categories

Want To Add Sky To Your Design?

Contact us today for a design consultation.