Factory For Plastic Pelletizing Machine - Stainless Steel Vertical Plastic Granules Mixer – Polestar

Factory For Plastic Pelletizing Machine - Stainless Steel Vertical Plastic Granules Mixer – Polestar Detail:

Description

Vertical plastic mixer is an ideal plastic mixer machine for mixing plastics, with the rapid rotation of the screw, the raw materials are lifted from the bottom of the barrel from the center to the top, and then scattered to the bottom by umbrella flying, so that the raw materials can be stirred up and down in the barrel, and a large number of raw materials can be evenly mixed in a short time.

Advantages

1.The plastic mixer machine is composed of mixing tank body, mixing tank cover, mixer, support, transmission device, shaft seal device, etc., and can be equipped with heating device or cooling device according to the process requirements; in the mixing process, the feeding control, discharge control, mixing control and other manual automatic control are available, which fully embodies the standardized and humanized design.

2.Mixing tank body, mixing tank cover, mixer, shaft seal, etc., can be made of carbon steel or stainless steel according to different process requirements. .

3.The mixing tank body and the mixing tank cover can be sealed with flanges or welded. The process pipe holes such as feeding, discharging, observation, temperature measurement, pressure measurement, steam fraction and safe emptying can be carried out according to the process requirements.

4.The upper part of the mixing tank cover is equipped with a transmission device (motor or reducer), and the agitator in the mixing tank is driven by the drive shaft. .

5.The shaft seal device can be in many forms, such as machine seal or packing, labyrinth seal and so on (determined according to the needs of users).

Technical Data

|

Model |

Power(kw) |

Capacity(KG) |

Dimension(mm) |

Rotating Speed |

Heating Power |

Blower |

|

BQX-500L |

2.2 |

500 |

1170*1480*2425 |

300 |

12 |

0.34 |

|

BQX-1000L |

3 |

1000 |

1385*1800*3026 |

300 |

18 |

1 |

|

BQX-2000L |

4 |

2000 |

1680*2030*3650 |

300 |

30 |

1.5 |

|

BQX-3000L |

5.5 |

3000 |

2130*2130*3675 |

300 |

38 |

2.2 |

|

BQX-5000L |

7.5 |

5000 |

3500*3500*3675 |

300 |

38 |

2.2 |

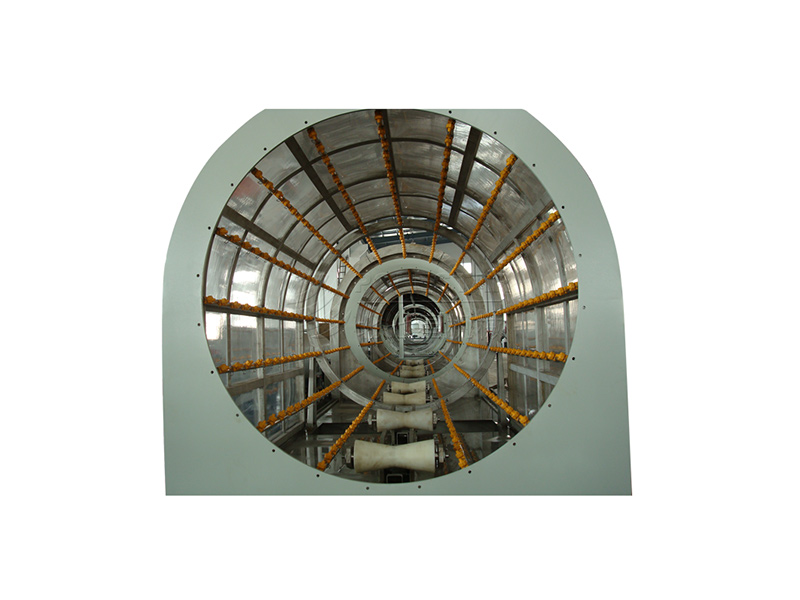

Product detail pictures:

Related Product Guide:

High quality Initial,and Buyer Supreme is our guideline to offer the ideal assistance to our shoppers.At present, we are striving our best to become amongst the ideal exporters inside our industry to satisfy shoppers more want for Factory For Plastic Pelletizing Machine - Stainless Steel Vertical Plastic Granules Mixer – Polestar , The product will supply to all over the world, such as: Vietnam, Vancouver, Iran, Based on our guiding principle of quality is the key to development, we continually strive to exceed our customers' expectations. As such, we sincerely invite all interested companies to contact us for future cooperation, We welcome old and new customers to hold hands together for exploring and developing; For more information, be sure to feel free to contact us. Thanks. Advanced equipment, strict quality control, customer-orientation service, initiative summary and improvement of defects and extensive industry experience enable us to guarantee more customer satisfaction and reputation which, in return, brings us more orders and benefits. If you are interested in any of our merchandise, make sure you feel free to contact us. Inquiry or visit to our company are warmly welcome. We sincerely hope to start a win-win and friendly partnership with you. You can see more details in our website.

The company's products can meet our diverse needs, and the price is cheap, the most important is that the quality is also very nice.

Products categories

Want To Add Sky To Your Design?

Contact us today for a design consultation.