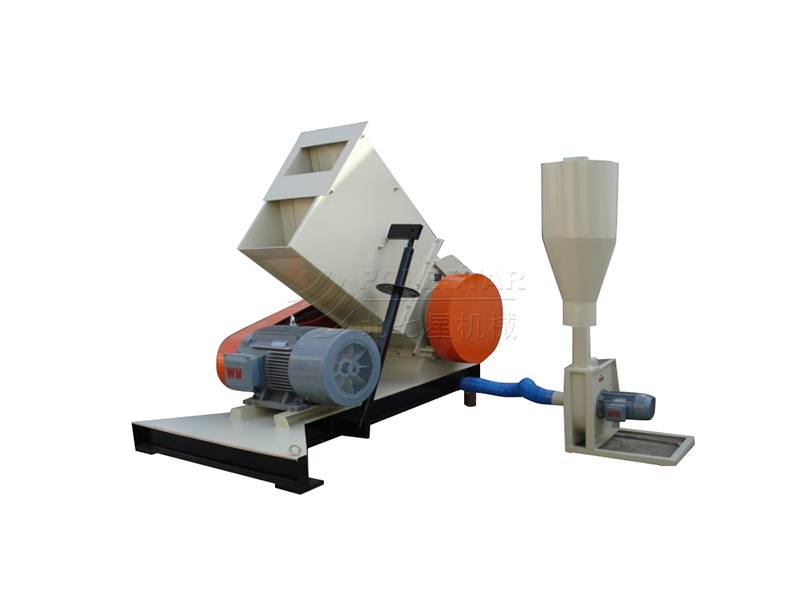

Excellent quality Extruder Profile - High Efficient Plastic Squeezer Machine for Films – Polestar

Excellent quality Extruder Profile - High Efficient Plastic Squeezer Machine for Films – Polestar Detail:

Description

Plastic squeezer machine is specially designed for dewatering film by squeezing mechanically. The final moisture content is around 3-5%. The material dried by this machine is widely used in granulating machine. They are very efficiency machines compared to hot air drying systems when considering energy consumption.

Model options with 200-1000kg/h capacity are available.

Features

* Stainless Steel Screen

The filer screen in the squeezing chamber is made of stainless steel,with the function of corrosion resistance and rustproof

* No Clogging of Screen

The filer screen are specially designed to prevent plastic material from clogging

* Final moisture within 5%

The final moisture of the material which are extruded by the dryer is 3-5%

Application

Plastic squeezer machine is specially designed for dewatering film by squeezing mechanically.

Competitive Advantage

Plastic film squeezer has less consumption, high working efficiency, and lower noise comparing the rotor type dewatering machine.

Pls tell us follow information to send quotation:

1) what raw material to deal?

2) what capacity require?

Plastic squeezer machine is not only with high capacity but also with low energy consumption. The final moisture content can up to 3-5%. It will help you reduce the cost and improve productivity. If you need more information, pls feel free to contact us!

Technical Data

| Model | GLS-250 | GLS-300 | GLS-320 | GLS-350 | GLS-380 |

| Capacity | 250Kgh | 400Kgh | 600Kgh | 800Kgh | 1000Kgh |

| Screw diameter | 250mm | 300mm | 320mm | 350mm | 380mm |

| Main motor | 55kw | 90kw | 110kw | 160kw | 160kw |

| Cutting blades | 4pcs | 4pcs | 4pcs | 4pcs | 4pcs |

Product detail pictures:

Related Product Guide:

Our mission is usually to turn into an innovative provider of high-tech digital and communication devices by furnishing benefit added design and style, world-class manufacturing, and service capabilities for Excellent quality Extruder Profile - High Efficient Plastic Squeezer Machine for Films – Polestar , The product will supply to all over the world, such as: Saudi Arabia, Angola, Birmingham, With strong technical strength and advanced production equipment, and SMS people purposefully , professional, dedicated spirit of enterprise. Enterprises took the lead through the ISO 9001:2008 international quality management system certification, CE certification EU ; CCC.SGS.CQC other related product certification. We look forward to reactivating our company connection.

We have been cooperated with this company for many years, the company always ensure timely delivery ,good quality and correct number, we are good partners.

Products categories

Want To Add Sky To Your Design?

Contact us today for a design consultation.