China Manufacturer for Plastic Bottle Shredder Machine - PVC WPC Wood Plastic Compounding Pelletizer Machine – Polestar

China Manufacturer for Plastic Bottle Shredder Machine - PVC WPC Wood Plastic Compounding Pelletizer Machine – Polestar Detail:

Description

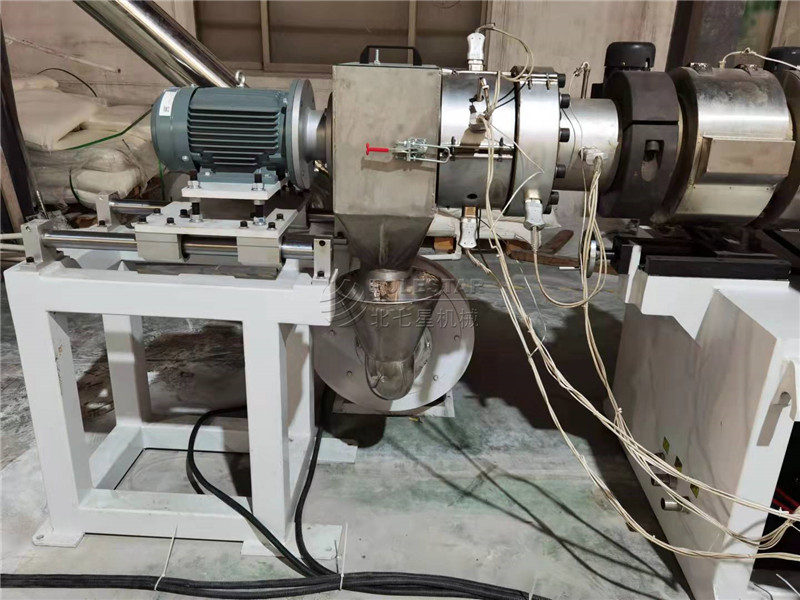

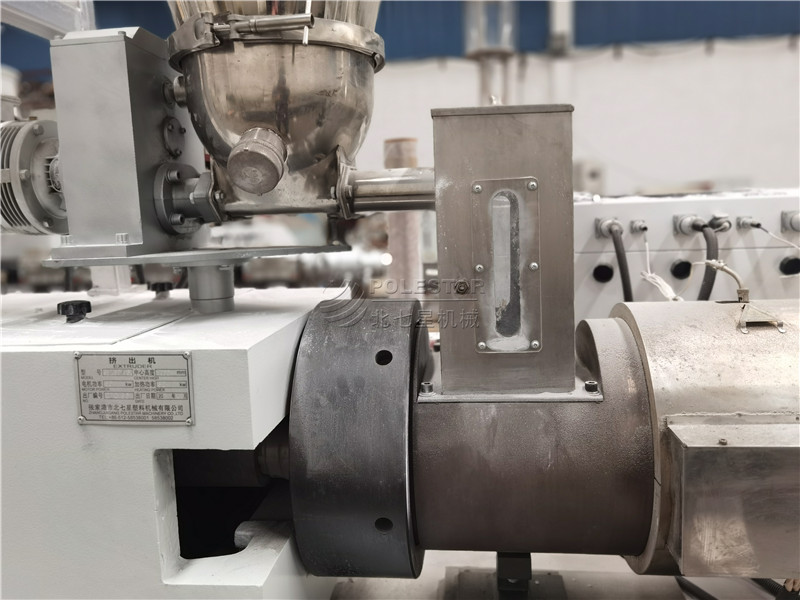

PVC granulating machine is widely used in various thermoplastic filling, compounding, improving modification, exhausting and vaporizing. In general, it is mixed with CaCO3 and some other additives before pelletizing.

PVC pellets is mainly used the conical twin screw extruder, adopts the die face hot cutting technology, with air cooling system to get good quality granules.

Competitive Advantage

1. Automatic PLC control

2. With individual temperature control

3. Convenient operation & Stable performance

4. Highly efficient, environmental protection and energy saving

Application

The pet pelletizing machine is is used to make PET plastic flakes into pellet or granule.Twin screw extruder recycling & pelletizing system are applied to the waste materials, which needs high processing performance of melting, volatilization, filtering etc.

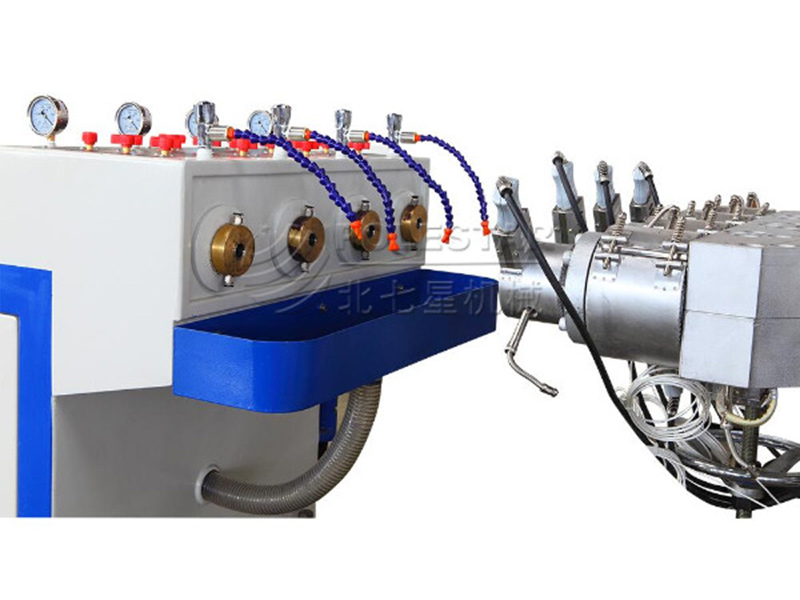

Die Head

. Mould durable with high quality carbon steel material and chrome plated treatment

. Reasonable flow outlet distribution ensures uniform extrusion without material interacting

Pelletizer

. Precision blades ensure the smooth section.

. Imported inverter achieved requirement for different pelletizing speed

Vibrator(Optional)

. PVC granules are filtered and graded through inertia vibrator.

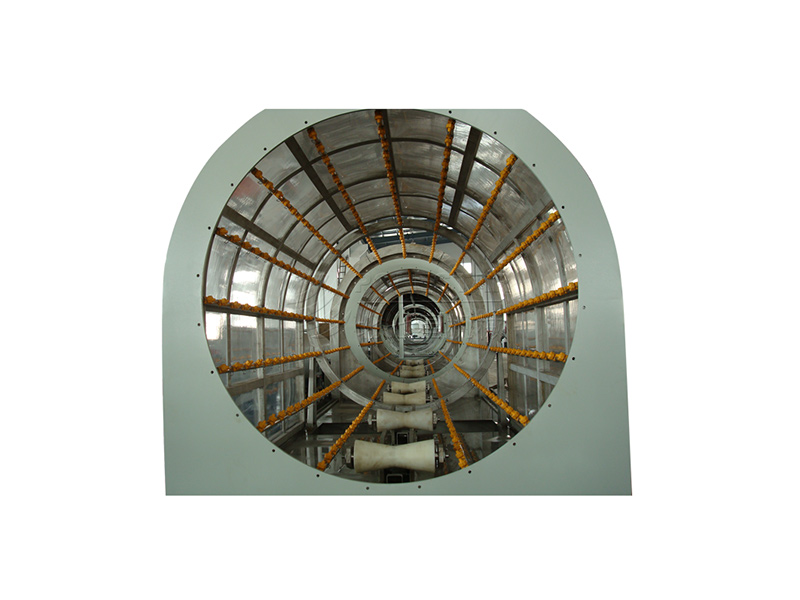

Cooling Device

. Unique three-dimensional cooling structure, higher cooling efficiency

. Multiple powerful fans combined with new cooling ideas, guarantee the quality of granules

Technical Data

|

Model |

grain size |

Drive Power |

capacity |

|

SJZ51/105 |

3-4mm |

18.5kw |

120-150 |

|

SJZ55/110 |

3-4mm |

22kw |

150-190 |

|

SJZ65/132 |

3-4mm |

37kw |

220-250 |

|

SJZ80/156 |

3-4mm |

55kw |

300-350 |

|

SJZ92/188 |

3-4mm |

110kw |

650-800 |

Product detail pictures:

Related Product Guide:

Reliable good quality and very good credit standing are our principles, which will help us at a top-ranking position. Adhering to your tenet of "quality 1st, purchaser supreme" for China Manufacturer for Plastic Bottle Shredder Machine - PVC WPC Wood Plastic Compounding Pelletizer Machine – Polestar , The product will supply to all over the world, such as: Dubai, Estonia, Hyderabad, We now have been making our goods for more than 20 years . Mainly do wholesale , so we've the most competitive price , but highest quality. For the past years , we got very good feedbacks , not only because we offer good solutions , but also because of our good after-sale service . We are here waiting for yourself for your inquiry.

The company leader recept us warmly, through a meticulous and thorough discussion, we signed a purchase order. Hope to cooperate smoothly

Products categories

Want To Add Sky To Your Design?

Contact us today for a design consultation.