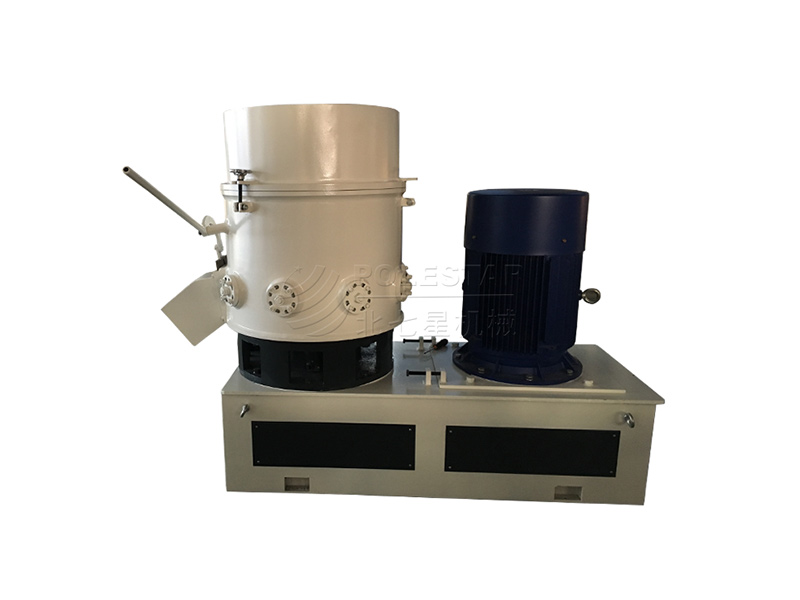

Plastic Agglomerator Machine for Plastic Recycling

Product Details

The plastic agglomerator machine / plastic densifier machine is used to granulate the thermal plastic films, PET fibers, whose thickness is less than 2mm into small granules & pellets directly. The soft PVC, LDPE, HDPE, PS, PP, foam PS, PET fibers and other thermoplastics are suitable for it.

Description

When the waste plastic is supplied into the chamber, it will be cut into smaller chips due to the crushing function of the rotating knife and fixed knife. During the crushing processing, the material that soaked up lots heat from the frictional movement of material being crushing and the wall of container will be going to become semi-plasticizing state. The particles will stick with each other due to the function of plasticization. Before it sticks each other completely, the cold water pre-prepared is sprayed into the material being crushed. The water will be evaporated off quickly and the surface temperature of material being crushed drop down quickly also. So the material being crushed will become small particles or granules. It is easy to recognize the particles by different size and can be colored by using of color agent being putted into the container during the crushing processing.

Features

Plastic densifier machine / plastic melter densifier working theory is different from ordinary extrusion pelletizer, no need electric heating, and can work whenever and wherever possible. It is jointly intelligent controlled by PLC& Computer, easy and stable for operations, and can save more electric power and manpower than common extrusion pelletizer. 2- strong design of double bearing for holding the main shaft,High performance blades,Water flushing automatically. 3-Used for changing PE, PP film/bags into agglomeration granules. Plastic agglomerator machine also called film agglomerator recycle a waste of the plastic film and wall thickness of less than 2 millimeters products direct granulation equipment.

Technical Data

|

GSL Series mainly used for PE/PP film, woven bag, non-woven bag, etc. |

||||||

|

Model |

GSL100 |

GSL200 |

GSL300 |

GSL500 |

GSL600 |

GSL800 |

|

Volume (L) |

100 |

200 |

300 |

500 |

600 |

800 |

|

Effective volume (L) |

75 |

150 |

225 |

375 |

450 |

600 |

|

Rotary blades (Qty) |

2 |

2 |

2 |

4 |

4 |

4 |

|

Fixed blades (Qty) |

6 |

6 |

8 |

8 |

8 |

8 |

|

Capacity (KG/H) |

100 |

150 |

200 |

300 |

400 |

550 |

|

Power (KW) |

37 |

55 |

75 |

90 |

90-110 |

110 |

|

GHX Series used for PET fiber to produce popcorn material |

||||

|

Model |

GHX100 |

GHX300 |

GHX400 |

GHX500 |

|

Volume (L) |

100 |

300 |

400 |

500 |

|

Effective volume (L) |

75 |

225 |

340 |

375 |

|

Rotary blades (Qty) |

2 |

2 |

4 |

4 |

|

Fixed blades (Qty) |

6 |

8 |

8 |

8 |

|

Capacity (KG/H) |

100 |

200 |

350 |

500 |

|

Power (KW) |

37 |

45 |

90 |

110 |

Products categories

Want To Add Sky To Your Design?

Contact us today for a design consultation.