2021 wholesale price Plastic Crusher Blade - Germany Technology Plastic PE PP Granulating Machine – Polestar

2021 wholesale price Plastic Crusher Blade - Germany Technology Plastic PE PP Granulating Machine – Polestar Detail:

Details

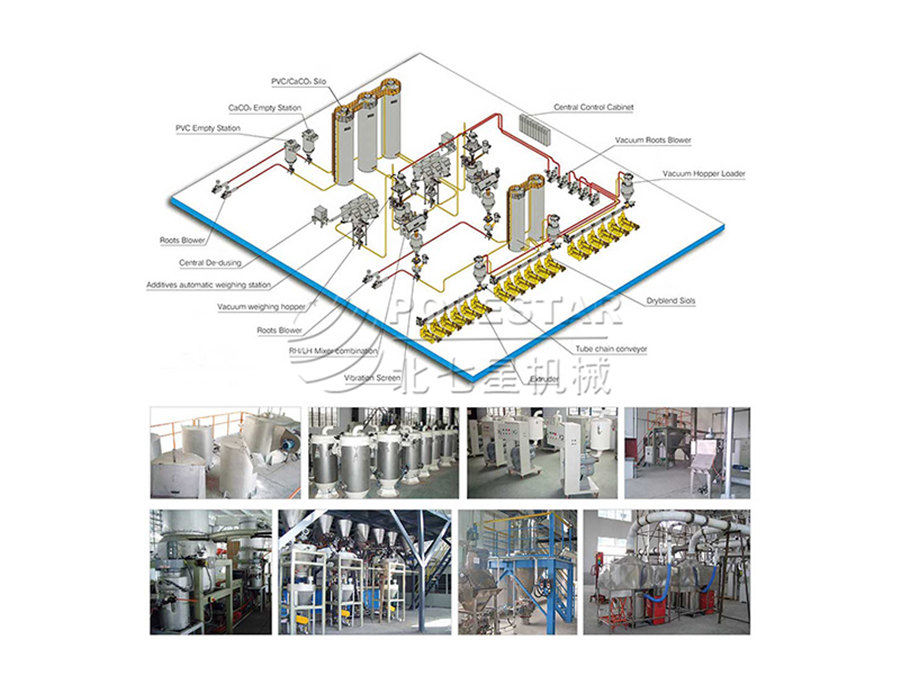

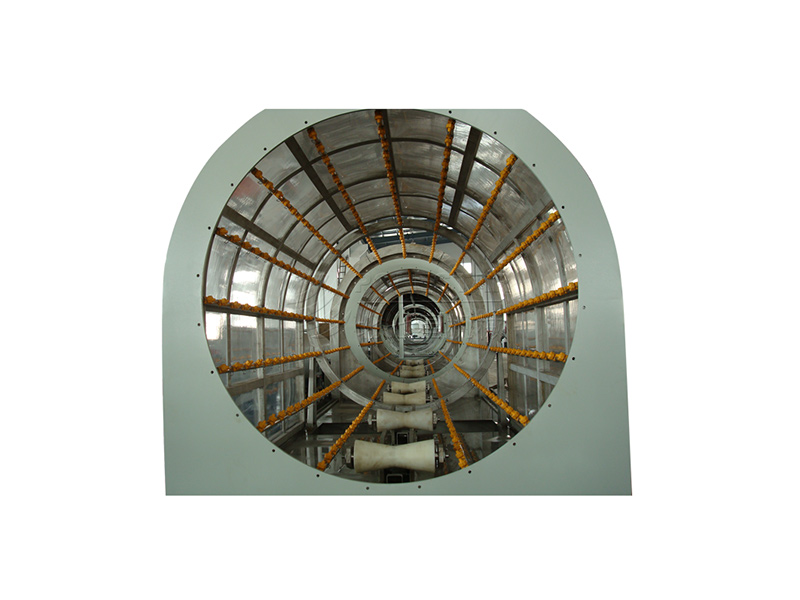

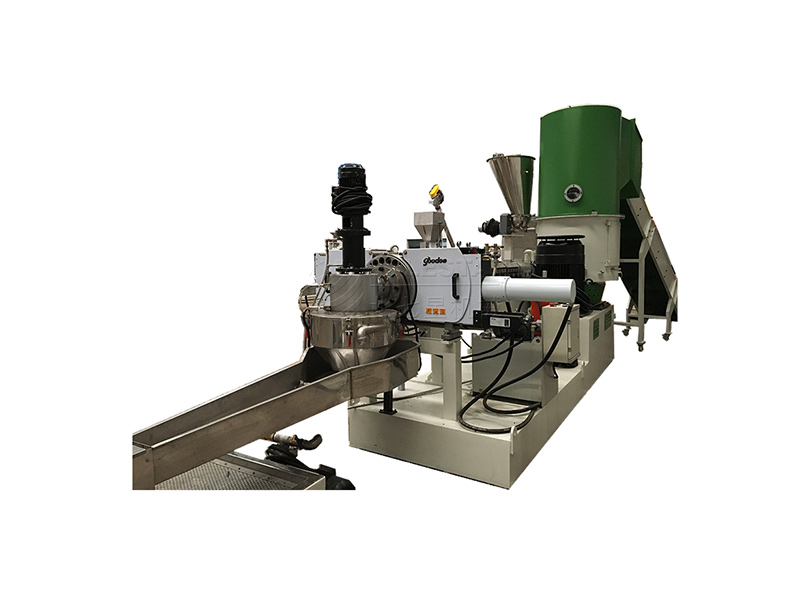

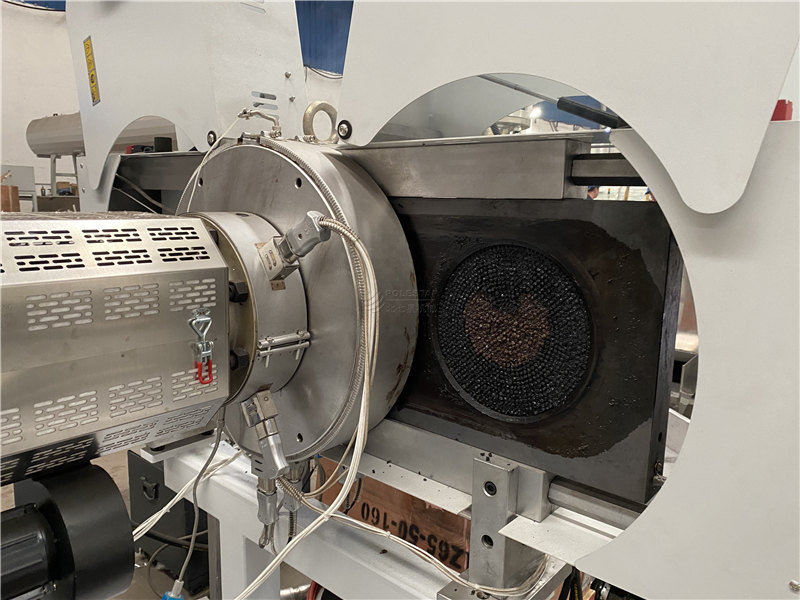

POLESTAR plastic pelletizer machine / Plastic Granulators that provides uniform heating distribution and homogenization is ideal for producing plastic pellets in recycling process. Plastic pelletizer machine are available in single (only one extrusion machine) and double stage arrangement (one main extrusion machine and one smaller secondary extrusion machine). It is recommended that to use double stage arraignment for recycling process due to the contamination in the plastic materials. There are also various options of plastic granule pelletizing technologies available to such as hydraulic assisted screen changer and double-piston screen changer to make sure there is no interruption during screen change. Our reliable gear box drives screw quietly to mix and move the molten plastic in the barrel. The screw that made of specially treated steel ensures against corrosion and abrasion. PID temperature control system with air or water cooling system maintains steady working temperature. “Hot Cut” water-ring die face pelletizing and “Cold Cut” strand pelletizing methods are available depending on your preference.

Application

Raw material: PE,PP Films and bags

Plastic granulator machine / plastic pelletizing machine / plastic pelletizer machine with agglomerator can be used for PE/PP film or PP woven bags and some parabolic pellet recycling, the materials will be compressed more tightened by agglomeration which will be easy threw to extrude to extrude, which can achieve maximum capacity 100-100kg/hour(depends on customers’ requirements)

Competitive Advantage

1. High automation level, try best to reduce your cost on labor and ensure high processing capacity.

2. Friendly control system (PLC integrated & separated control on each machine) and Touch screen panel, easy for operation, monitor and emergency stop.

3. All parts contacting with plastic material and water are made of high-quality 304 stainless steel; Ensure no second pollution to flakes.

4. Siemens contactor,RKC temperature controller

Main Features

1. Highly automatic, user-friendly control, highly efficient, environmental protection and energy saving;

2. Different pelletizing ways, such as cold strand, water-ring, and underwater for various raw materials and production requirements;

3. Multi-stations screen changer and automatic screen changing design can reduce manual labor and improve operation convenience;

4. Single and double stage, multi-exhaust and filtering system ensure high quality and products;

5. Suitable for diverse materials processing, also can specially design the machine for one material or different materials, which can reduce customer’s investment cost.

Technical Data

Single stage agglomeration granulation line

|

Model |

70 |

100 |

120 |

150 |

180 |

|

Output (kg/h) |

70-120 |

200-250 |

300-400 |

500-600 |

700-850 |

|

Power consumption (kWh/kg) |

700-850 |

||||

|

Main power (kW) |

37 |

90 |

110 |

132 |

185 |

|

Agglomerator power(kW) |

30 |

55 |

75 |

110 |

132 |

|

Screw outer diameter (L/D) |

70(33:1) |

100(30-35:1) |

100(30-35:1) |

100(30-35:1) |

180(30-32:1) |

|

Vacuum exhaust |

Option |

||||

|

Screen changer |

Standard configuration |

||||

|

Water-ring granulation |

Option |

||||

|

Cold strand granulation |

Option |

||||

|

Underwater granulation |

Option |

||||

Double stage agglomeration granulation line

|

Model |

70+90 |

100+120 |

120+150 |

150+180 |

180+200 |

|

Output (kg/h) |

110-180 |

200-300 |

300-450 |

500-650 |

700-850 |

|

Power consumption (kWh/kg) |

0.2-0.35 |

||||

|

Main power (kW) |

30+22 |

75+37 |

90+45 |

110+55 |

160+75 |

|

Agglomerator power(kW) |

30 |

55 |

75 |

110 |

132 |

|

Screw outer diameter(L/D) |

70(25+12:1) |

100(25+12:1) |

120(25+12:1) |

150(25+12:1) |

180(25+12:1) |

|

Vacuum exhaust |

Option |

||||

|

Screen changer |

2 sets of standard configuration |

||||

|

Water-ring granulation |

Option |

||||

|

Cold strand granulation |

Option |

||||

|

Underwater granulation |

Option |

||||

Product detail pictures:

Related Product Guide:

Our eternal pursuits are the attitude of "regard the market, regard the custom, regard the science" as well as theory of "quality the basic, have faith in the initial and administration the advanced" for 2021 wholesale price Plastic Crusher Blade - Germany Technology Plastic PE PP Granulating Machine – Polestar , The product will supply to all over the world, such as: Marseille, Moldova, Plymouth, We will do our utmost to cooperate & satisfied with you relying on top-grade quality and competitive price and best after service ,sincerely look forward to cooperating with you and make achievements in the future!

Production management mechanism is completed, quality is guaranteed, high credibility and service let the cooperation is easy, perfect!

Products categories

Want To Add Sky To Your Design?

Contact us today for a design consultation.