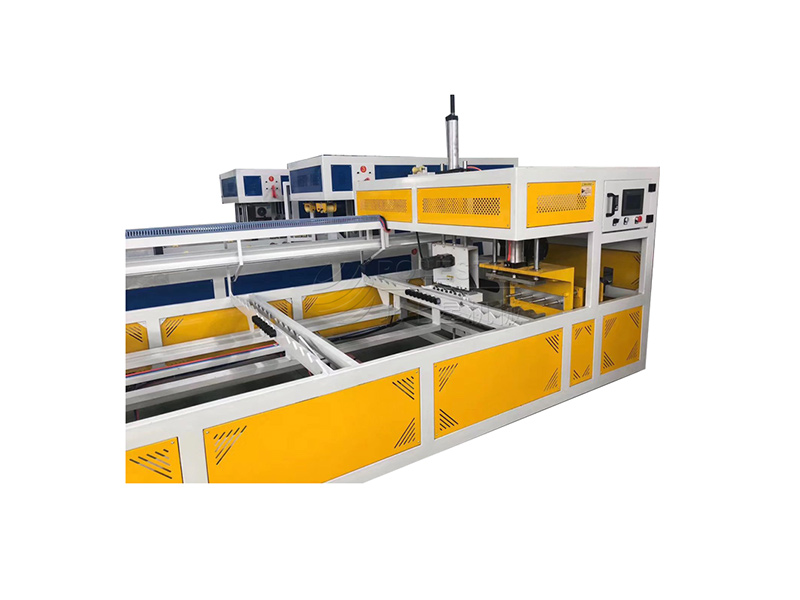

2021 Good Quality Single Stage Pelletizing Machine - TSK Series Parallel Twin Screw Extruder – Polestar

2021 Good Quality Single Stage Pelletizing Machine - TSK Series Parallel Twin Screw Extruder – Polestar Detail:

Characteristics

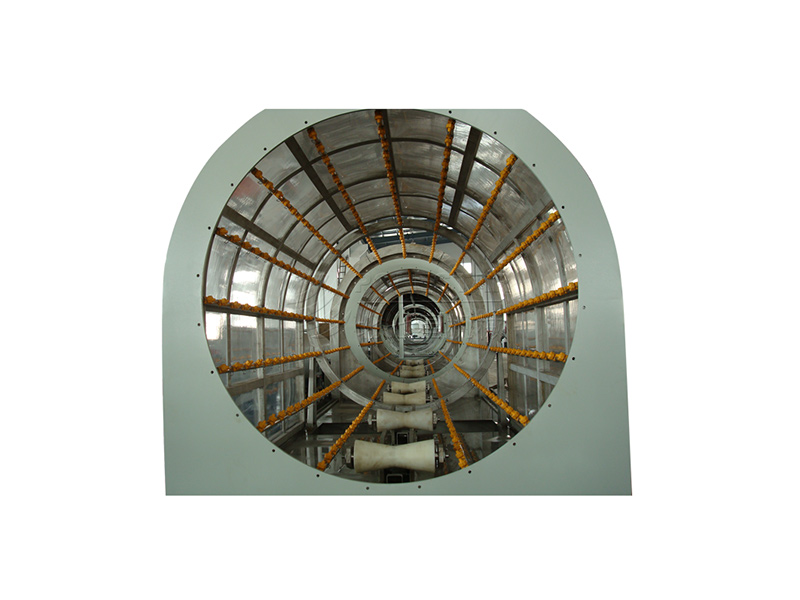

TSK Parallel twin screw extruder is a kind of high-efficiency compounding and extruding equipment. Twin screw extruder core section is composed of “00″type barrel and two screws, which mesh with each other. Twin screw extruder has driving system and control system and control system, feeding system to form a kind of special extruding, granulation and shaping processing equipment. The screw stem and barrel adopt building type design principle to change the length of the barrel, choose different screw stem parts to assemble the line according to material characteristics, so as to get the best work condition and max function. Because it has good mixing, separating, dewatering and self-cleaning functions to avoid the materials wrapping the axle, caking in the extruding process. With the rotation of the screw, the surface of the materials continuously change, helps the volatile matter dewater, treat, and etc.

Application

The co-rotating parallel twin-screw extruder is suitable for PP, PE, PVC, PA, PBT, PET and other materials. It is suitable for the laboratories of universities, colleges and research institutes for process testing, formula development, etc. The equipment has the characteristics of beautiful appearance, compact structure, convenient application and maintenance, and accurate control of process conditions.

Main Technical Parameter

|

TSK-35 |

TSK-50 |

TSK-75A |

TSK-75B |

TSK-95 |

|

|

Screw DIA(mm) |

35.6 |

50.5 |

62.4 |

71.2 |

91 |

|

Screw speed(r/min) |

600 |

500/600 |

500/600 |

500/600 |

400/500 |

|

Main motor power(KW) |

15-22 |

37-55 |

55-110 |

75-160 |

220-315 |

|

L/D |

32-52 |

32-52 |

32-52 |

32-52 |

32-48 |

|

Capacity (kg/h) |

30-60 |

80-180 |

150-350 |

300-500 |

600-1000 |

Product detail pictures:

Related Product Guide:

Trustworthy good quality and excellent credit score standing are our principles, which will help us at a top-ranking position. Adhering towards the tenet of "quality first, buyer supreme" for 2021 Good Quality Single Stage Pelletizing Machine - TSK Series Parallel Twin Screw Extruder – Polestar , The product will supply to all over the world, such as: Australia, Saudi Arabia, Serbia, We hope we can establish long-term cooperation with all of the customers. And hope we can improve competitiveness and achieve the win-win situation together with the customers. We sincerely welcome the customers from all over the world to contact us for anything you need!

Timely delivery, strict implementation of the contract provisions of the goods, encountered special circumstances, but also actively cooperate, a trustworthy company!

Products categories

Want To Add Sky To Your Design?

Contact us today for a design consultation.