16-32mm PVC Pipe Four Output Extrusion Line

Description

PVC pipe four output extrusion line, 16-32mm diameter, for water supply and drain.

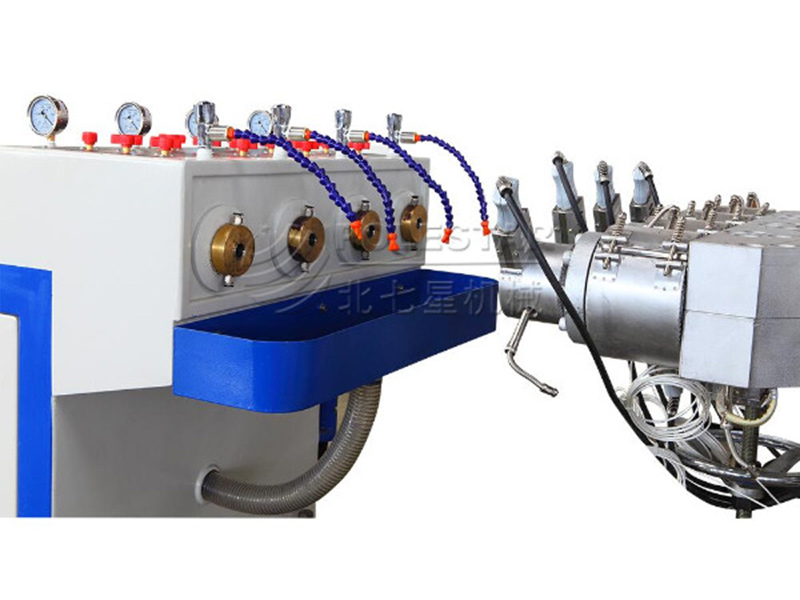

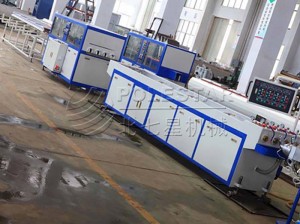

PVC pipe production line compose by: loader--extruder--mould--vacuum calibration tank--haul off--cutter--stacker

PVC pipe machine can process various soft and rigid PVC, especially process powder directly into pipe shape. PVC pipe line machine consists pvc pipe extruder, vacuum calibration tank, haul-off unit, stacker or belling machine, etc. The pipe extruder machine and haul-off unit adopt AC inverters. PVC plastic pipe extrusion line electric parts are international well-known brand products, which guarantee quality of machine. The PLC and big true-color screen panel make control system with high automation.

Application

PVC four pipe extrusion line, 16-32mm diameter, for water supply and drain.

4 cavity PVC electrical tube, water supply pipe extrusion line can extrude four pipes at same time on one machine.

This line can save investment cost in factory building and production,which increase the capacity a lot and reduce production time. SJSZ65 conical twin-screw extruder can easily reach 5.5-6.5 ton/day,the production speed take 16mm as example can get more than 8-10m/min.

The whole line is composed of conical twin screw extruder dia 65mm,4 cavity mould,4 cavity cooling calibration tank, 4 station haul-off,4 station cutter,and 4 station tipping table.

Competitive Advantage

Produce four pipes at same time, can save investment coat in factory building and production,increase the capacity a lot and reduce production time.

304 stainless steel made, ABB inventer. Wannan motor.

Made more stronger for standard parts. It can use for much more long time.

Meet with CE standard.

Technical Data

| Product Name: | PVC four pipe extrusion line |

| Electric consumption(KW): | 100 kw / h |

| Water consumption(Tons): | 3 tons per hour (the water can be recycled) |

| Working voltage: | 380V, 3PHASE, 50HZ(based on customer’s requirements) |

| Capacity (kg/h): | 270kgh(based on customer’s requirements) |

| Diameter: | 20mm-32mm |

| Max hauling speed (m/min) | 10 |

Products categories

Want To Add Sky To Your Design?

Contact us today for a design consultation.