20-110mm PPR Pipe Extrusion Line

Application

PPR pipe machine can be used for the following applications:

Conveyance of potable water

Hot and cold water transportation

Underfloor heating

Central heating installations in houses and industries

Industrial transportations (chemical fluids and gasses)

PPR pipe machine special applications (undersea networks, networks with a high risk of electrochemical corrosion etc.)

Description

Compared with PE pipe, PPR pipe can be used to transport hot water. Usually, it is used inside building for hot water supply. Nowadays, there are many kinds of PPR pipe, for example, PPR fiberglass composite pipe, also PPR with uvioresistant outer layer and antibiosis inner layer. Our PPR pipe extrusion line can fully satisfy customer requirement. Our PPR pipe making machine can process wide range of material, including HDPE, LDPE, PP, PPR, PPH, PPB, MPP, PERT, etc. Our PPR pipe extrusion line can produce from size of minimum 16mm to 160mm with single layer or multi-layer or even multi-layer with double cavity to save machine cost and operation cost.

Ppr Pipe Extrusion Machine Advantage

A. L/D=38, double mixer and barrier screw, which can ensure 100% plasticization before going into die, with spiral groove on feeding part, it increases 30% of productivity.

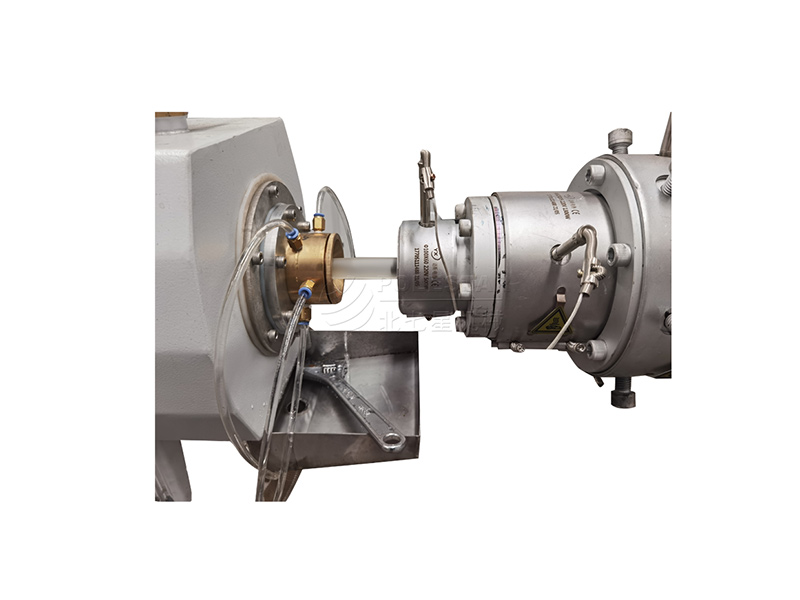

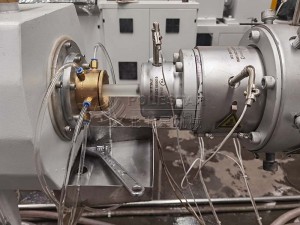

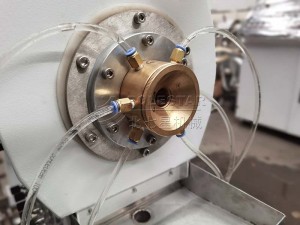

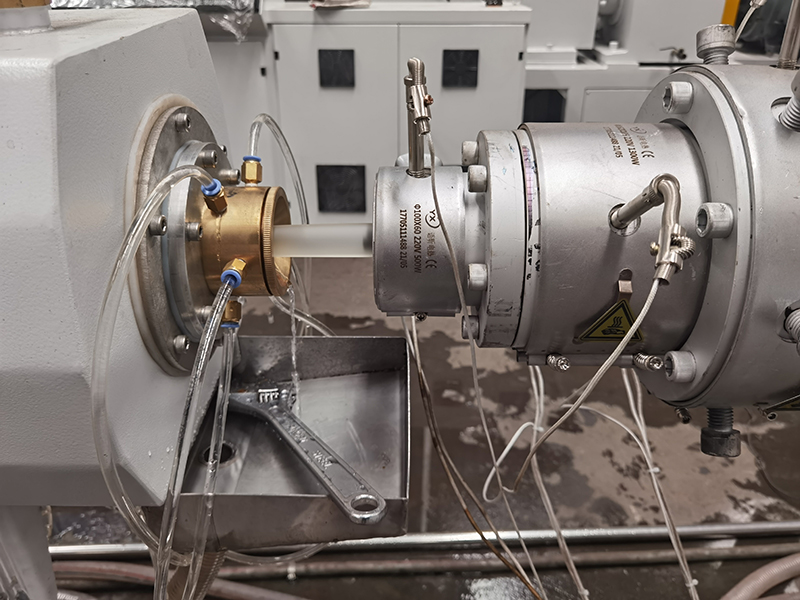

B. Die with spiral mandrel, it ensures no delay in the flow channel which can improve pipe quality.Particular disc design on calibration sleeves which ensures high speed extrusion.

C. Double-strand vacuum tank is controlled individually, which makes convenient operation as single one.Stable and reliable pressure transmitter and vacuum pressure sensor are adopted to realize automatic control.

D. Double haul-off is also controlled individually which makes convenient operation as single strand,additionally, with the upper caterpillar belt stop device, to ensure roundness of pipe.

E. With individual designed of chipless cutter. Driven by motor and synchronous belts which ensures normal cutting during high speed running.

Technical Data

| Model | 60/38 | 75/38 | 90/38 | 120/38 | |

| Application | Raw material | Output | |||

| Water & Gas | PE | 500 | 650 | 1100 | 1350 |

| Antistatic coating | PE-RT | 400 | 600 | 1000 | 1200 |

| Water & Fitting | PP-R | 350 | 520 | 800 | 1100 |

| Drainage & Sewage | PP | 350 | 520 | 800 | 1000 |

Products categories

Want To Add Sky To Your Design?

Contact us today for a design consultation.